Table of Contents

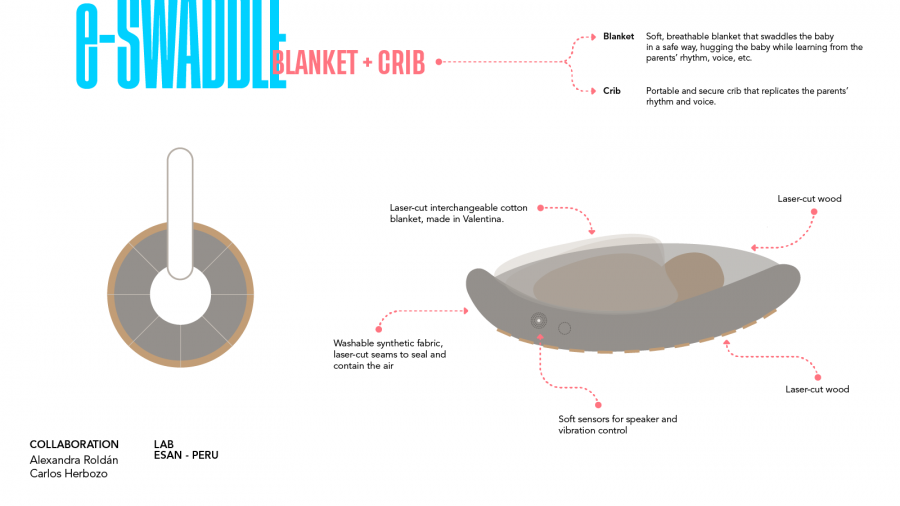

FINAL PROJECT: "e- swaddle"

Carlos and I are working together for the final Project.

After testing many ideas, we found a:

REAL LIFE + KNOWN SITUATION +EASY TO APPROACH SUBJECT

So, tired mom, has to go to work , carry the baby around and carry many things for her and the baby.

THINGS THAT (KIND OF) WORK

OTHER THINGS ON THE MARKET

Thinking of all this, talking to moms, hearing their needs and worries;

WHAT WE ARE WORKING ON

PRODUCT PERSONALIZATION

The blanket and crib would be manufactured using digital fabrication techniques and materials. The design can be personalized (mostly the blanket) using 2D design software like Illustrator or Photoshop, or even CorelDraw and Rhinoceros. Tools like laser cutters can be used to fabricate the textile pieces.

SYSTEM PERSONALIZATION

The blanket must be designed using parametric tools like grasshopper so that it is able to be modified to fit every baby. Also, if the design is modular, then more pieces can be added, thus making a bigger blanket as the baby grows.

SERVICE PERSONALIZATION

The idea that the system is completely integrated is what gives this project the ultra personalization at a service level. When the blanket “learns” the movement of the parents and sends it to the crib, this moves at a rhythm that's unique for every baby. Every parent moves differently, and every crib will move differently, so the movement is personalized to fit the baby's needs.

BOM!!!!

These are the materials we are most likely to use during the development of the project:

Cotton fabric (for the blanket)

Synthetic fabric (for the crib)

Plywood (for the base)

Conductive yarn (for the stretch sensor)

Conductive copper thread (for the fabric speaker)

Neodymium magnets (for the speaker)

ATtiny 45 (controlling the movements of the crib and the monitoring of vitals)

Glycerine (for bioplastics)

Jelly (for bioplastics)

Starch (bioplastics)

Vinegar (bioplastics)

Conductive thread for soft electronic plaques

DC motor for the locomotion system

L298 modulus for the locomotion system

HOW IT´S GOING

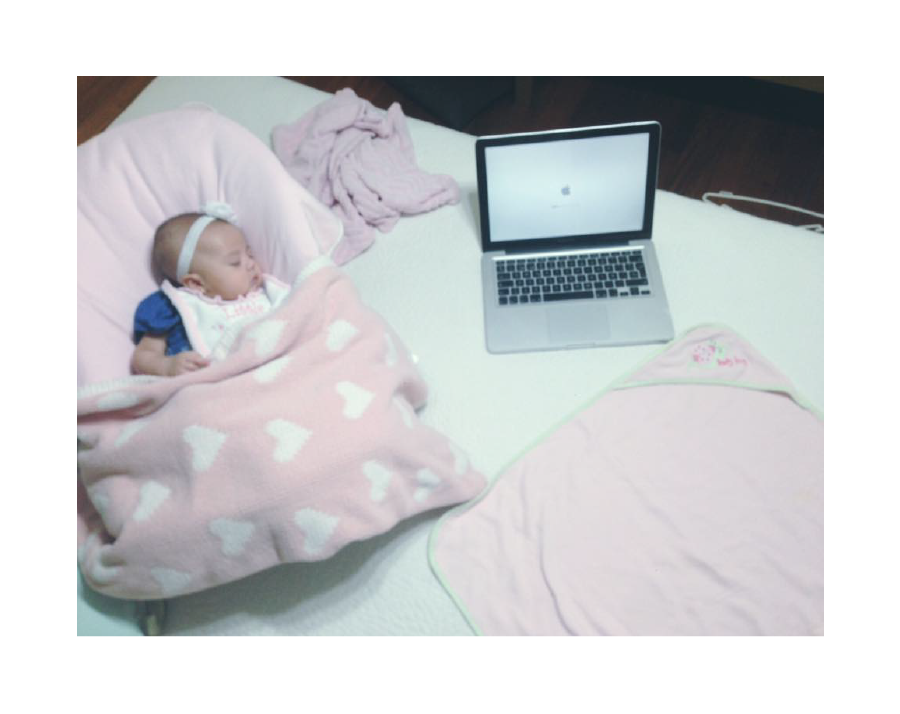

My niece is the inspiration and subject of experimentation of this project.

I began “swaddling” her with a regular blanket following Youtube tutorial to see it this was really comfortable.

The “swaddling” situation is not common with Peruvian mom´s and my sister was looking at me with dudes in her face, but we tried anyway.

THE RESULT

GOOD PART: The baby seemed comfortable and relax on the swaddle.

BAD PART: To swaddle the baby with a normal blanket, it has to be very big and you need a big place, to lay it and the baby.

SIZING IT

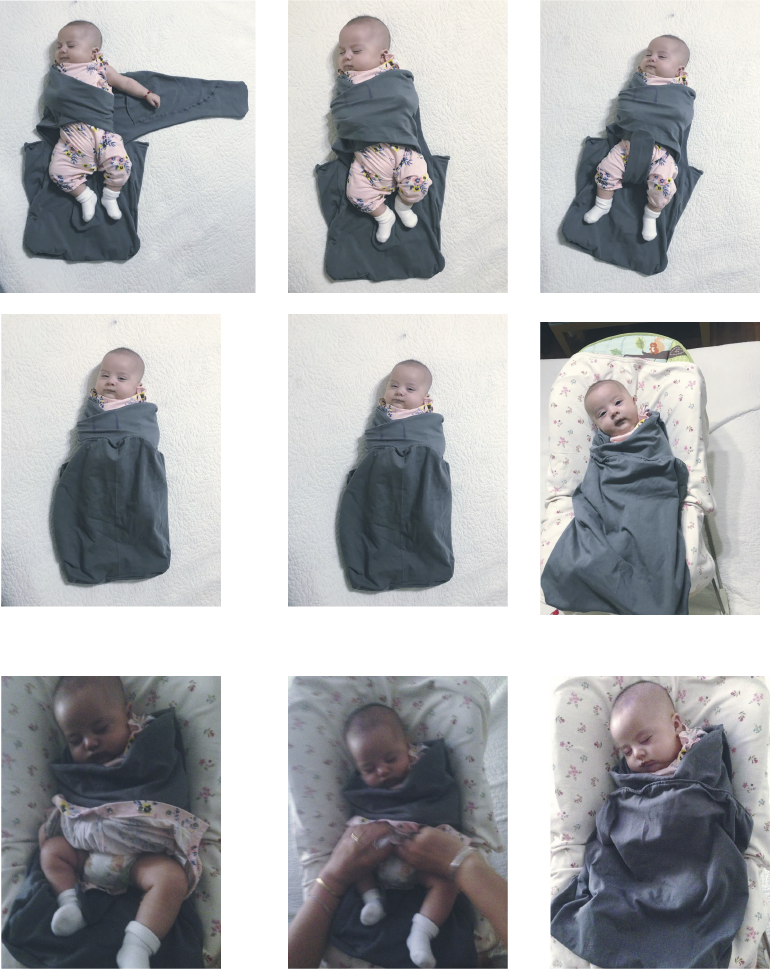

I took my niece´s measurements, she is 3 months old now and according to our research the “swaddling” age is from zero to six months old.

After the baby starts to move and rotate, it´s not to safe to have the baby in that position.

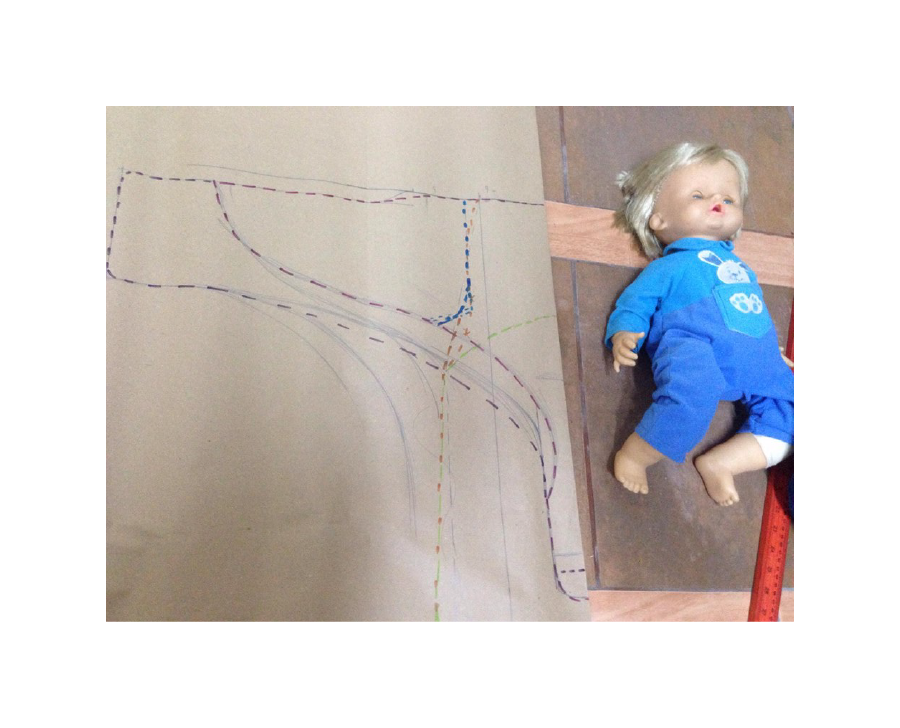

Found a doll that has a similar size tan Mikella, so she became our dummy.

Because being pattern that I´ve never done before and have no guide on how to make it.

I made the first trial on paper, then, we will re-do it and fix it in Valentina.

And then cut it in a trial fabric.

SEWING

TESTING

1.Swaddle the baby

2.Let her sleep in the bed with mom

3.Take her to the vibrating chair

4.Diaper change trial

DIAPER CHANGE TRIAL

The baby seemed very comfortable, she didn´t wake up at all, to change her diaper, her mom has able to do it just by removing the bottom part of the swaddle, so Mikella could keep sleeping and didn´t get cold.

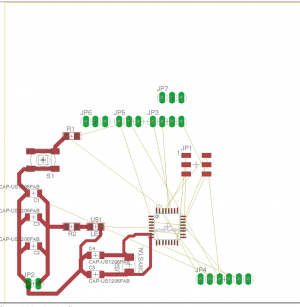

ELECTRONICS

Our plan for the electronics is this:

Blanket: mic + acelerometer+ bluetooth

Crib: bluetooth+ speaker+ engine for the movement

In the Textiles assignments, both of us have been experimenting with soft sensors and hand sewing conductive ink as a test for the final Project.

Sadly, there are things like conductive ink, smaller microphone and the fabspeaker components that we do not have in the lab, but we are trying to buy them and hopefully they´ll be in time for us to try them and make it work for the final presentation, if not, we will resolve with what we have here, for the first prototype.

CRIB

After a lot of research on user experience, we found out that the possibility of having the inflatable crib was not something the mom´s wanted. They say that the possibility of its suffocating the baby will discourage them from using the product.

So we opted for a foam crib.

We had interesting feedback from Cecilia about how to find the right fabrics and foams for the baby. We are looking at it and searching for someone that can ship it to Lima (yes, for some reason , many don´t want to do it)

We used common crib mattress foam for our first trials.

First the foam had to be cut to fit in the laser machine and then we cut the modules on it.

Power 60

Speed 2

Frequency 100 hz

FILES: https://drive.google.com/drive/folders/1BUaBUdzylVz9bFzfJGGDNlQ0CY4lAxq5