Table of Contents

Week 07. The Textile Scaffold

Program outline

composites crystallization solidification textile formwork concrete casting

Materials

Ecoflex Borax, rochelle salt, potasium sodium. UV resin Concrete

Assignment

Each student can use a different technique to make a prototype of a technical textile application

Hands On

*Textile Scafold in HandMade Paper*

I choose to use HandMade Paper as material, or use the cotton pulp to construct my forms, using the fabric as Scaffold and mold to the final form.

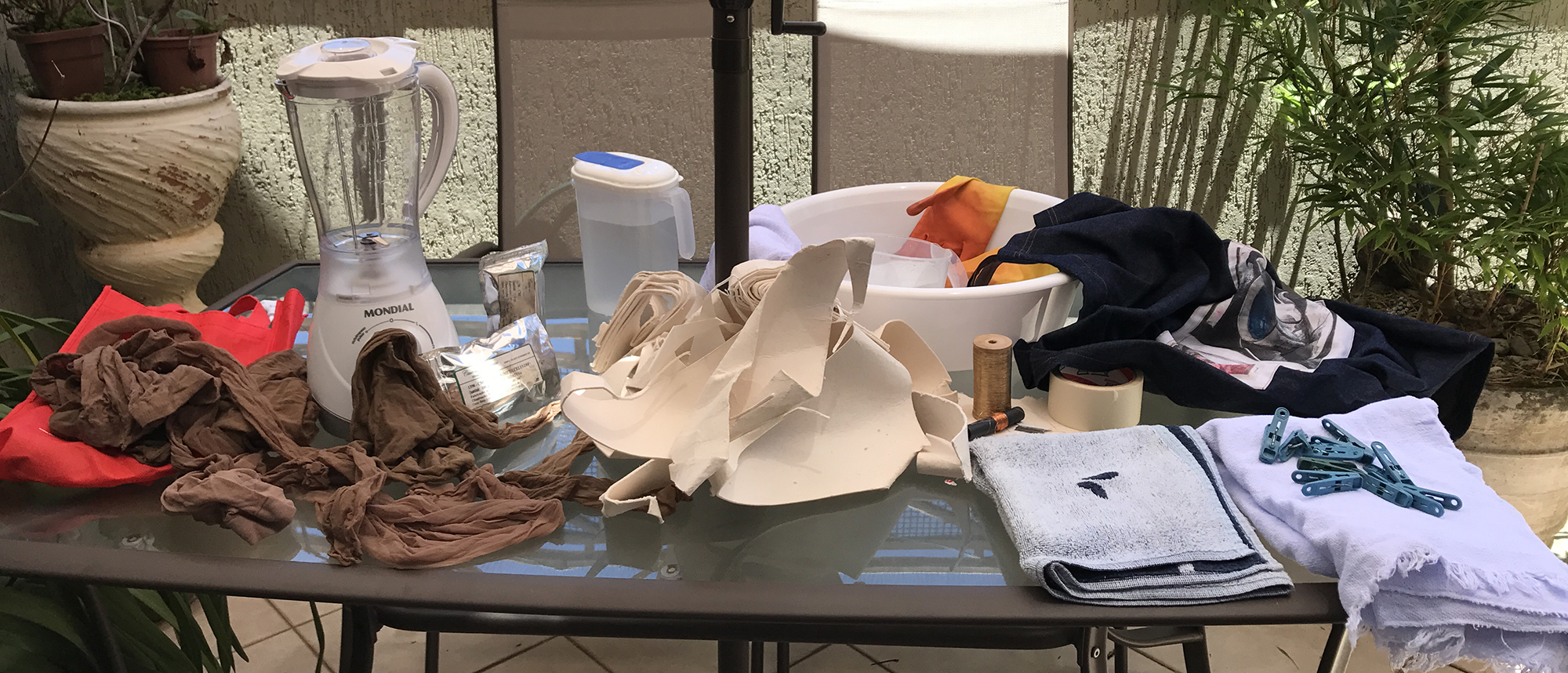

01 Preparing the Materials

Materials and instruments

Cotton Linter

Silk stockings

CMC Carboxymethylcellulose

Water

Blender

Bowl

Sieve

TNT Fabrics

Threads

clothes fasteners

Cotton Bag Cloths

Receipt

Cotton

- 100 g of Cotton Linter ( cotton filter scrap )

- Divide in small pieces

- Wet in water in a 10 liters bowl

- Shake in one liter of water in little amounts

CMC solution

- Put a soup spoon of CMC in one liter of water and shake

Pulp preparation

- Use one cup of the CMC solution to the 10 liters bowl with cotton pulp

- The Pulp has to be put in small amounts

- Mix everything with the hands in the bowl until you have an homogenous suspension of the cotton pulp

Paper preparation

- Use the sieve to collect thin layers of pulp from the bowl

- invert the sieve over a thin stretch fabric , like TNT

- remove the excess of water with a cloth

- let it dry

- remove the paper from the fabric stretching the fabric when paper is completely dry.

Composites

- You can insert materials inside the paper, as a composite ( dry flowers, natural pigments, used tea

- Forming the paper in layers and inserting the materials between one layer and another

Mixed technique

- Also you can insert condutive thread to produce some electronic with paper.

Scaffold

- You can mold the paper format with the fabric itself stretching and locking the fabric with the wet pulp or using a external mold to put the fabric with the wet pulp.

The stop motion with all the process is here ! <3

*Crystallization*

Salt Crystals

Materials

coarse Salt

filtered water

clean clear glass container

pan

string

gimp

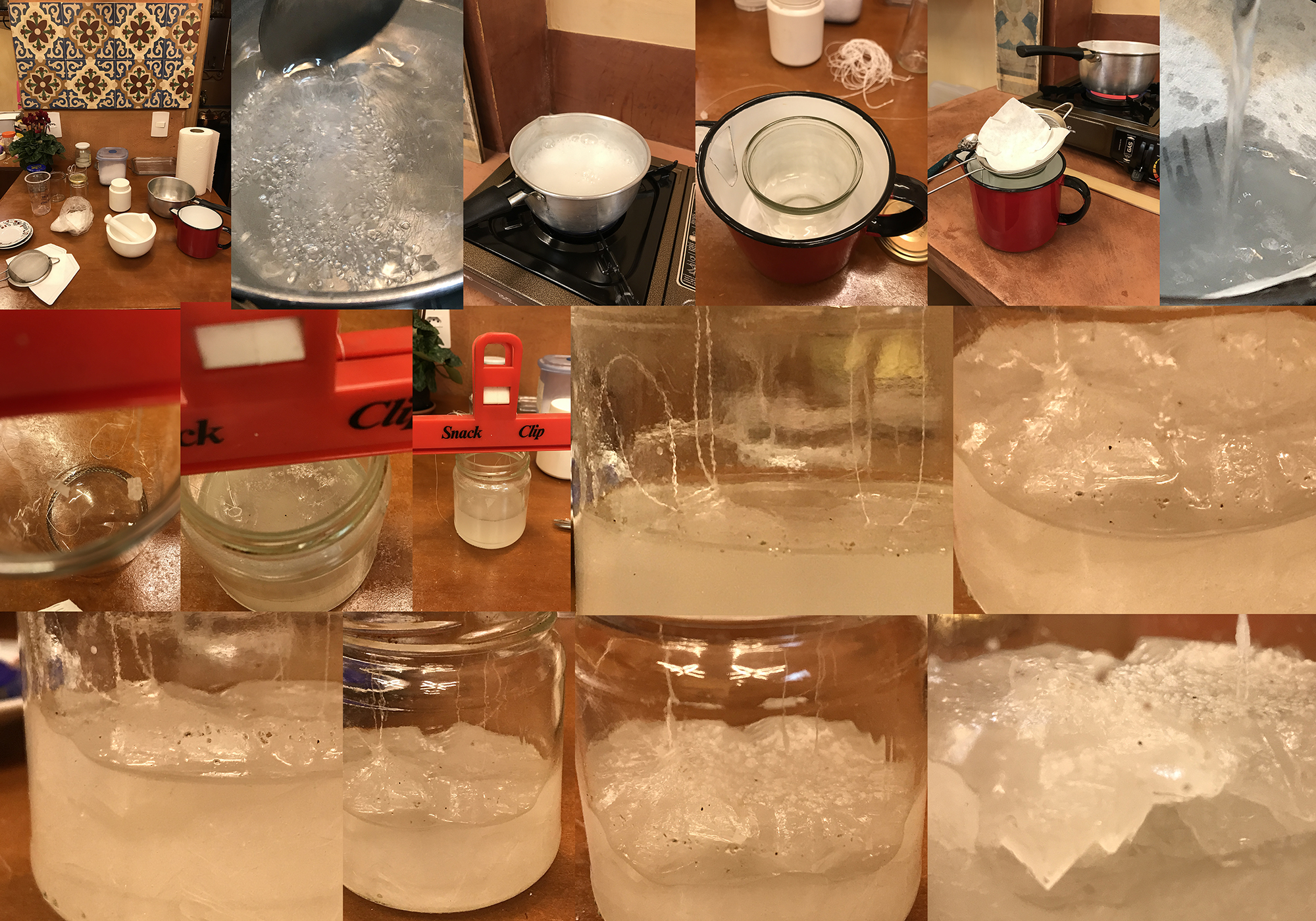

Recipe

- Heat the water in a pan, until boiling.

- Go adding the coarse salt and spinning until complete dissolution.

- Add salt until it no longer dissolves and begin to drop crystals in the bottom.

- Heat another portion of water and pass through the filter, sieve and vial before filtering the final solution.

- Note: I did not do this the first time and the solution crystallized already in the filtering.

- Filter the solution directly into the preheated glass clean bottle.

- Insert the string with a small crystal seed, into the super saturated salt solution.

- Attach the string on top so that the seed crystal remains inside the solution but cleared from the walls or the bottom.

Execution

Results

Alum Crystals

Materials

Alum

filtered water

clean clear glass container

pan

silk thread

gimp

Recipe

- Heat the water in a pan, until boiling.

- Go adding the Alum and spinning until complete dissolution.

- Add Alum until it no longer dissolves and begin to drop crystals in the bottom.

- Heat another portion of water and pass through the filter, sieve and vial before filtering the final solution.

- Filter the solution directly into the preheated glass clean bottle.

- Insert the silk thread with a small crystal seed, into the super saturated Alum solution.

- Attach the silk thread on top so that the seed crystal remains inside the solution but cleared from the walls or the bottom.

- After 24 hours drain the rest of the solution.

- Remove the crystal by gently pulling the silk thread.

Execution

Results

Problems

In my case, 24h was too much time, I shoud have take the crystal off before, because the glass was no so big and as I've put two seed crystas, they grew so much that they clung to one another, I had to gently release them with a very thin, pointed spatula, and one of them escaped from the thread, but the other stayed intact and the final result was amazing !