Table of Contents

Open Source Hardware:

From fibers to fabrics

Due to my curiosity, additively fabricate large-scale structures made of water-based materials, I decided to make my own Gelatine-based bio-plastic 3D printer.

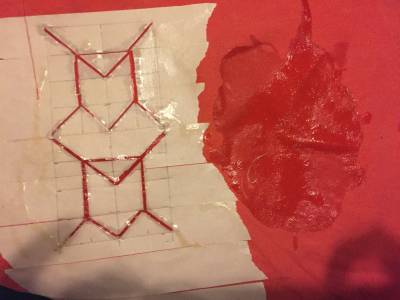

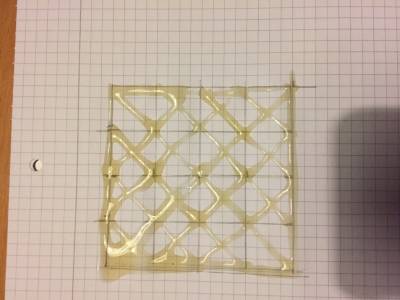

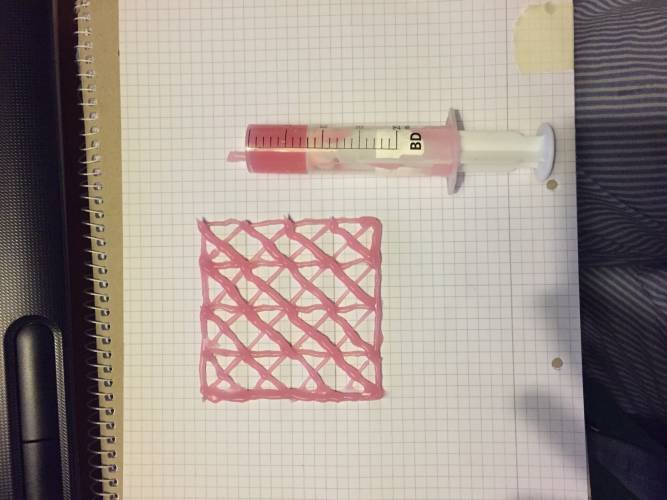

The first idea was to make a 3D printer which has double extruder controller. First syringe extruder should provide the more rigid amount of material(structure) and the second one should be more flexible(surface). I made my gelatine-based biomaterial with different ratios. I basically keep the same amount of water and glycerine ratio and systematically increase gelatine ratio(1-2-4-8). But despite my many trials when every ratio of gelatine-based materials interface with each other lost their shape and they harmonized with each other. Then I try with corn starch-based bio-material. Starch-based bio-material performance well together.

Bio-Material 3D printer

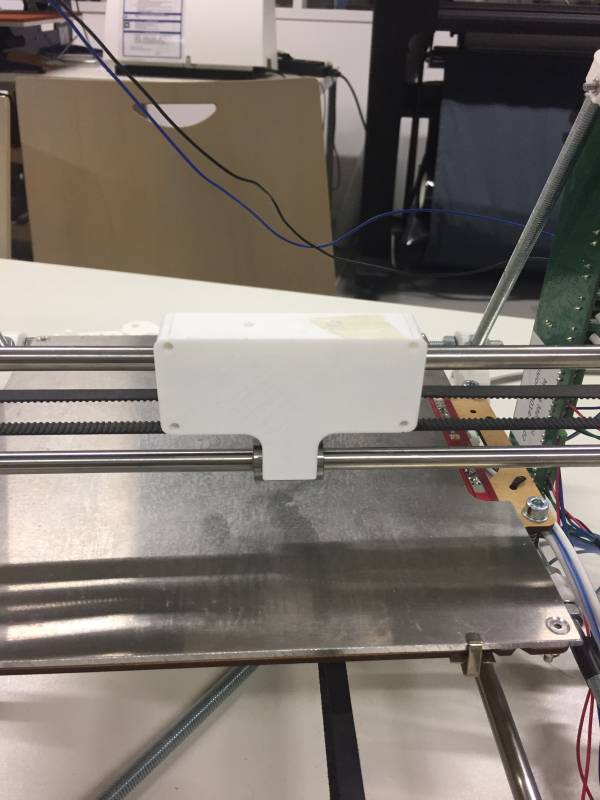

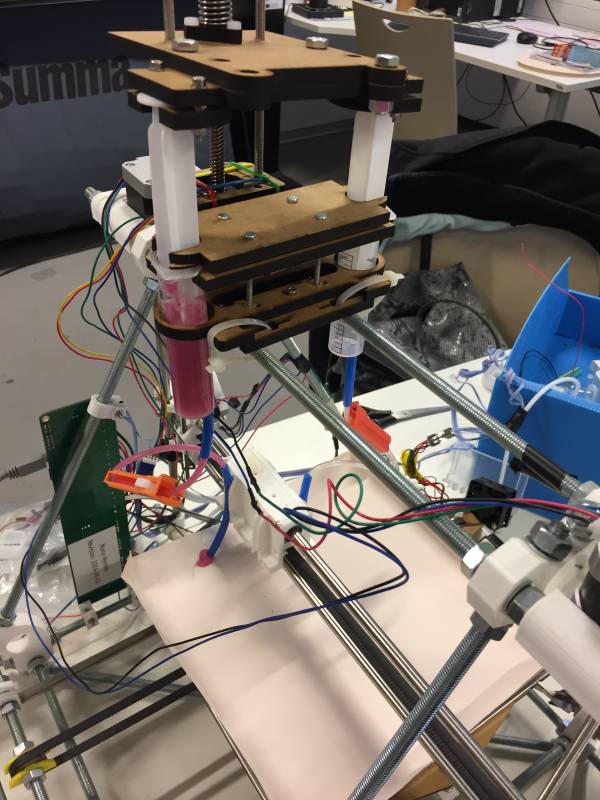

I converted RepRap tricolor mendel printer into bio-plastic 3d printer.

First ı tried many ratio's in the bio-plastic.

As you can see from the chart, ı stabilize the amount of water and glycerine and only play with the gelatine amount. ^ ^glycerine ^water ^gelatine |

| Left | x | 20x | 4x |

|---|

| middle | x | 20x | 8x |

|---|---|---|---|

| left | x | 20x | 16x |

First ı tried diffrent ratio's. Turned out for ratio 3/4 water gelation is a good performance.

I tried on fabric, I wanted to see if the fabric could take the shape of my lines and would it be bending. But it did not work. Bio-Material is soaked by the fabric and when its dry it completely crack when ı stretch the fabric.

For my 3D printer, I tested out Gelatine based bio-material with other Bio-plastics.Gelatine is not working well with other gelatine based material. They are melting with each other.

| Cornstarch-based bio-material colored by blackberry | glycerine | Cornstarch | vinegar | water |

|---|---|---|---|---|

| ratio's | x | 3x | 2x | 12x |

Hacking the RepRap

Check this link from the reached out whole documentation of RepRappro tricolour.n

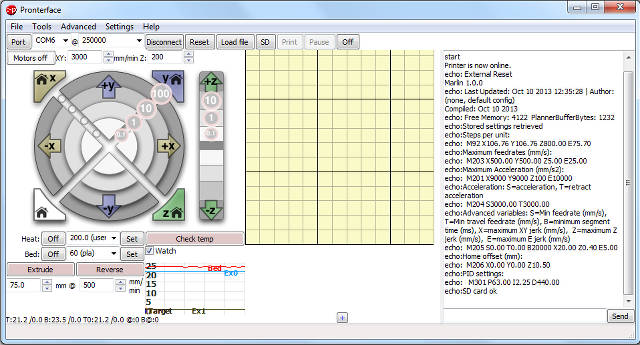

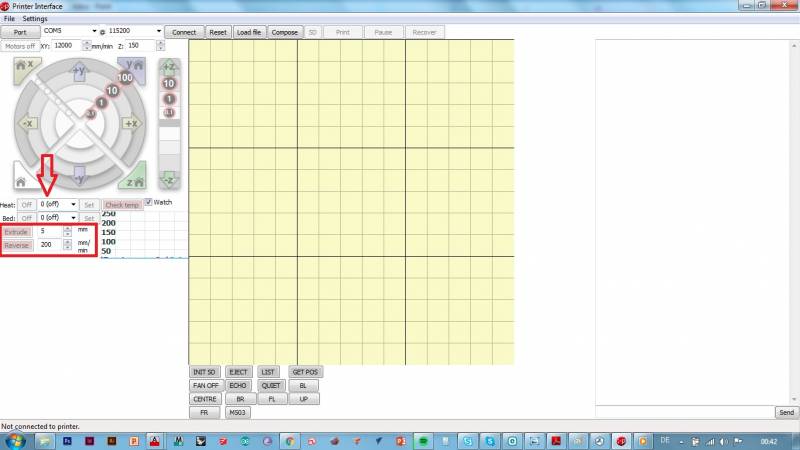

For control The machine I downloaded [[http://www.pronterface.com/|printrun]] which is a 3D printing host software suite

which talks to your printer and handles the printing process.

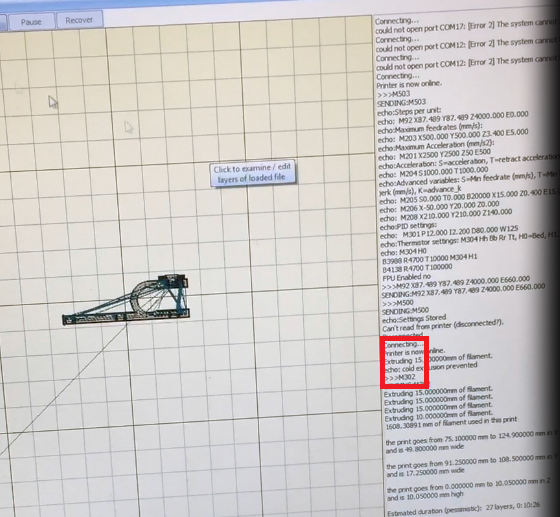

But this ss for normal fdm settings. What we should is that turn off the bed temp. and extruder temp.

The idea is to first remove filament extruder and replace with my new syringe extruder design. When the servo motor of the extruder moves extra structure that ı designed would push the syringes and create a shape by following pipes.

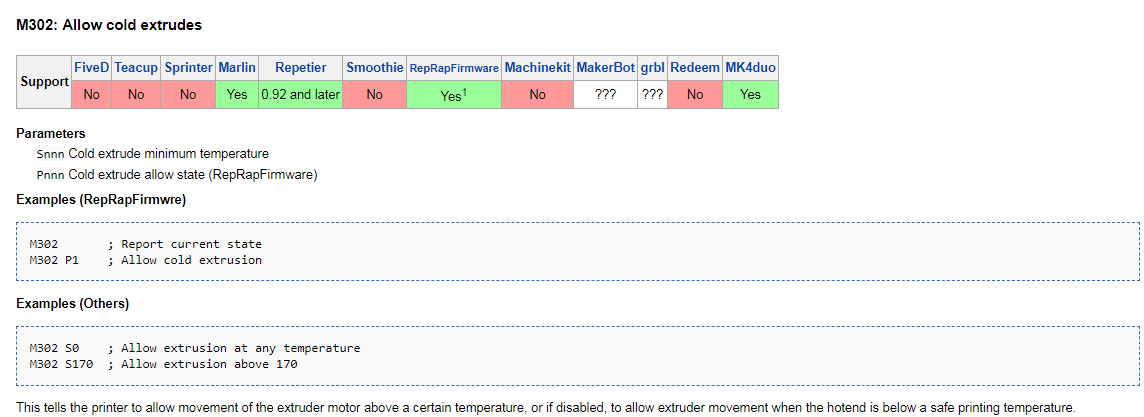

so when you remove the filament extruder, you have to run the machine without heating the extruder heat. That's why you have to use G-code m302 code.

http://reprap.org/wiki/G-code#M302:_Allow_cold_extrudes

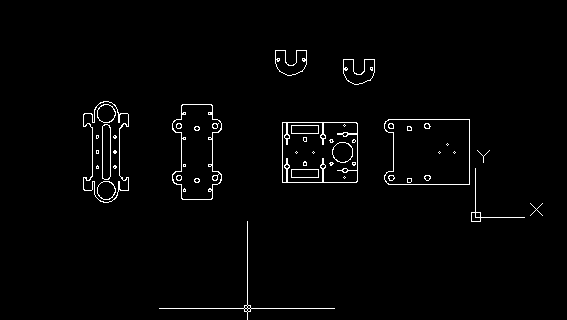

Design syringe extruder

There are not many syringe extruder example in the internet actually. I actually used this design and changed as 3d files to 2d to cut with the laser cutter.

I took the section views of the parts and extended as one pieces also for carry two syringe at the same time.

https://www.youtube.com/watch?v=pQZ7nPtEXKQ

https://www.youtube.com/watch?v=YrH1otV9-To&feature=youtu.be

.