Table of Contents

Soft Robotics

For this assignment we were given the choice between 3 different tasks:

- Basic: Pneumatic brace

- Intermediate: Soft gripper

- Advanced: Other control structures

I decided to focus on the gripper because I had some experience with robotics but did not have enough time for focusing on creating a more complex system.

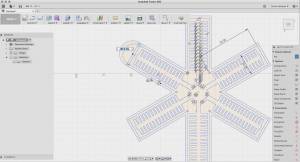

First attempt

Instead of downloading the files directly from the web, I designed my own soft gripper using Fusion 360. In order to increase the strength of the grip, my device was formed by six arms rather than just four. Here's a picture of the design. This is not what the gripper would look like, rather, this is a negative of how it would look like. I saved the finished body as an STL and sent it to the print environment.

This is not what the gripper would look like, rather, this is a negative of how it would look like. I saved the finished body as an STL and sent it to the print environment.

I used a “MakerBot replicator +” since these are the 3D printers available at my university. The parameters were the following:

- Material: Translucent PLA (polylactic acid)

- Extruder temperature: 219 °C

- Rafts: yes

- Support: not needed

- Infill: 10%

- Layer Height: 0.2

- Raft to model spacing: 0.36

Because of the size of the design (about 20 cm long), it would take 10 hours for it to print, so I had to change it.

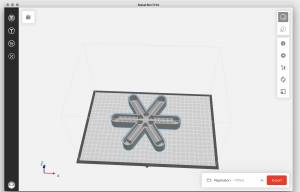

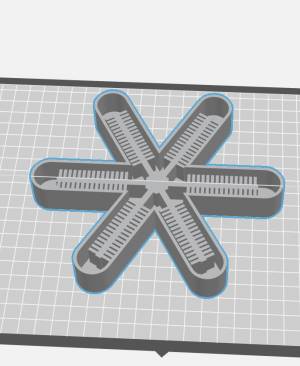

Second Attempt

I changed my design to a 6 cm wide-4-armed-gripper. I then used the same printing parameters and printed my mold in only 51 minutes. These are the files

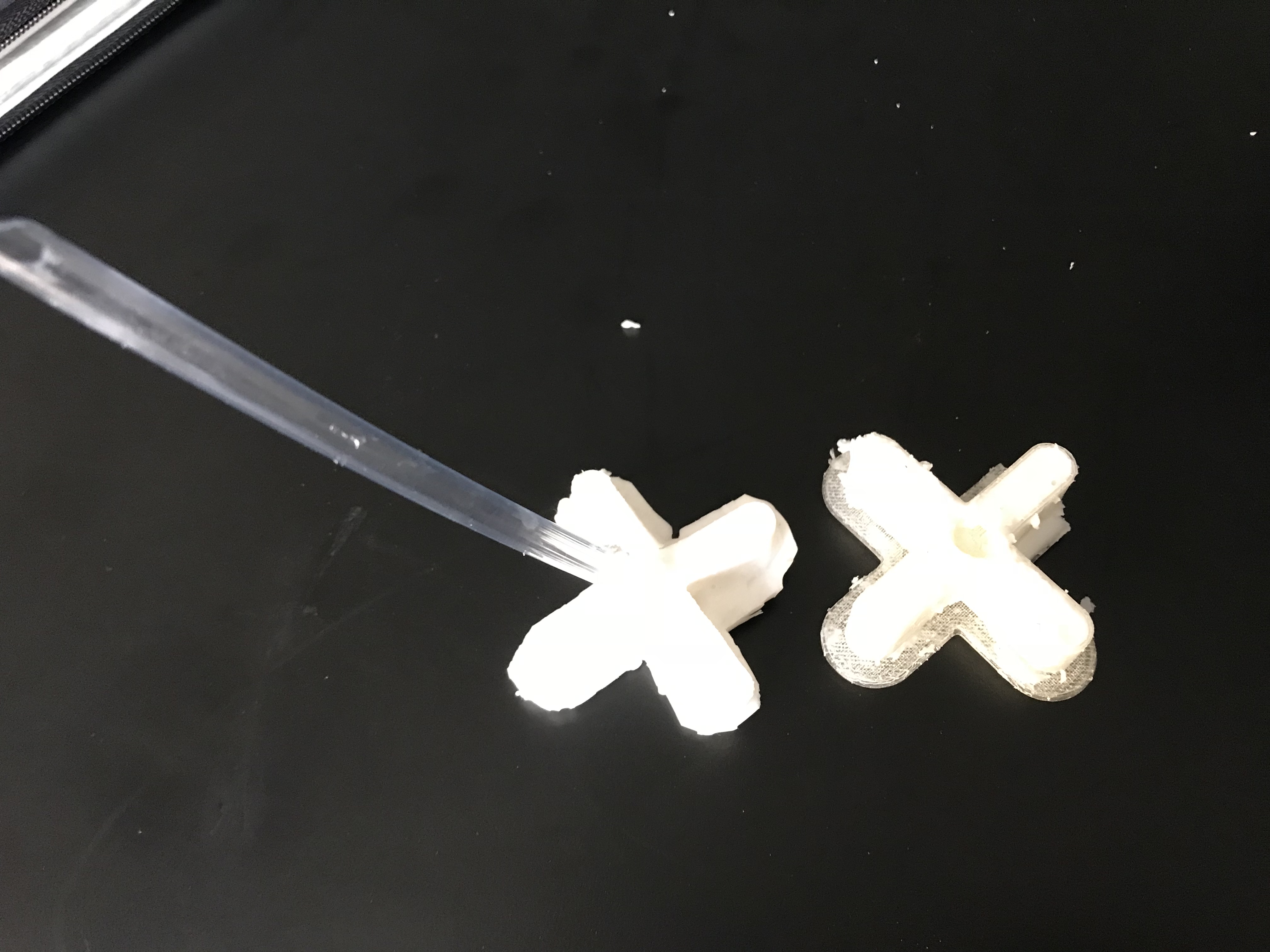

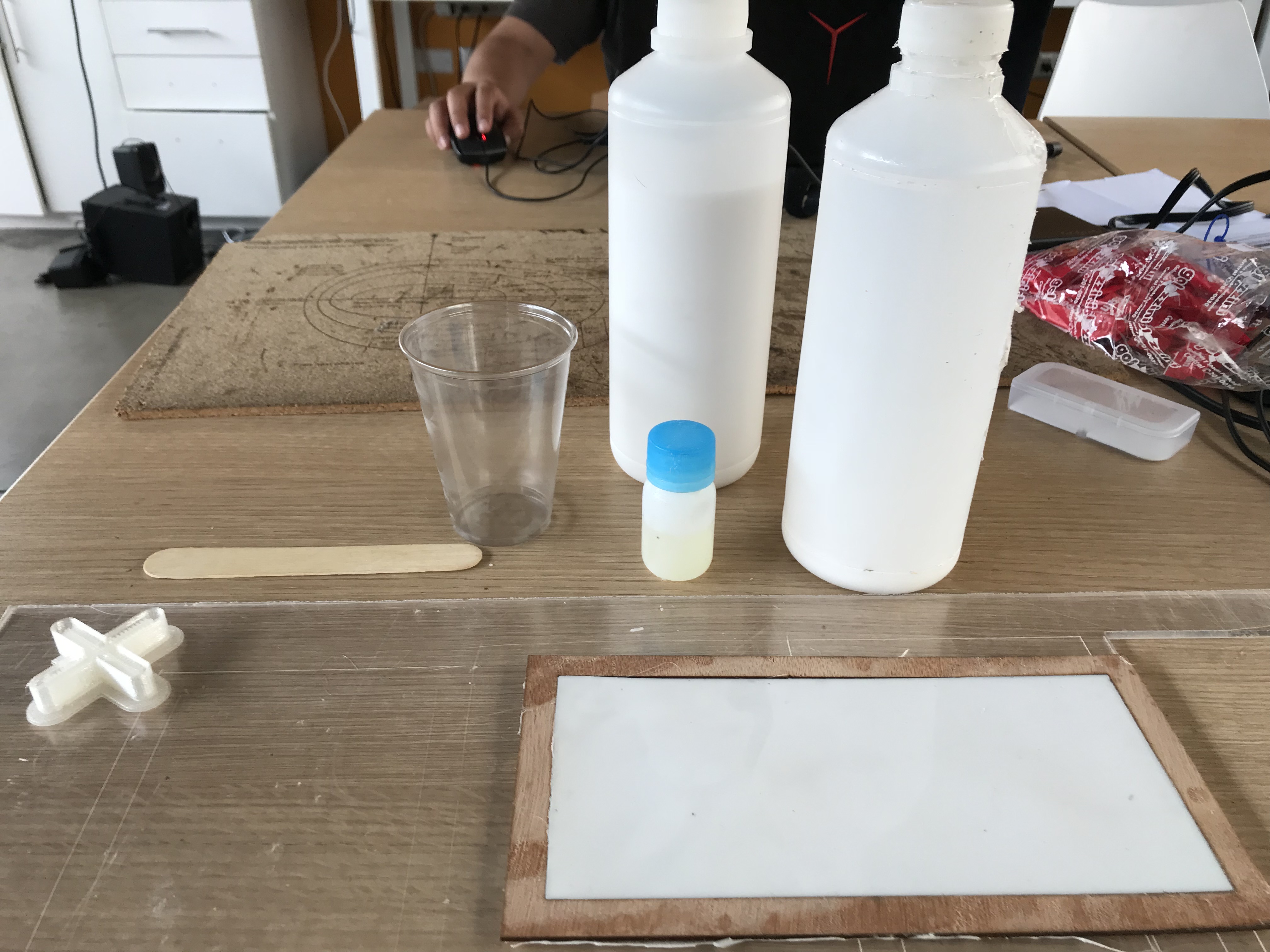

I then proceeded to cast the material, thus generating the actual soft gripper. I used silicone and a catalyzer to accelerate the curing process. I used 70 grams of silicone and an amount of catalyzer equal to 6% of the silicone's weight. After 30 minutes it was completely cured.

After the gripper was cured, I “glued” it to a flat silicone surface, using even more silicone. The problem, however, was that the surface wasn't completely flat, so I later discovered that there were air leaks. Another issue was that the tube I used for inserting air wasn't attached to the gripper. This also generated leaks. These problems led me to try for a third time.

The problem, however, was that the surface wasn't completely flat, so I later discovered that there were air leaks. Another issue was that the tube I used for inserting air wasn't attached to the gripper. This also generated leaks. These problems led me to try for a third time.

Third Attempt

This time I used the same parameters as before, except for the fact that I tried to insert the tube while the silicone was curing so that it would be stuck with the gripper. This did not work, however, because silicone will stick to silicone and to silicone only, meaning that this gripper has a hole in the middle.