Table of Contents

Week 6: Computational couture

This week's assignment was to create a parametrical pattern using Grasshopper, the plugin for Rhino, and 3D print it. I created 2 designs - one 3D printed on fabric and one stand alone design. Both were printed using flexible filament. To download the file for the weave, visit: https://oscircularfashion.herokuapp.com/project/-L6RBZO2WvKMLb8Uni3l

First design

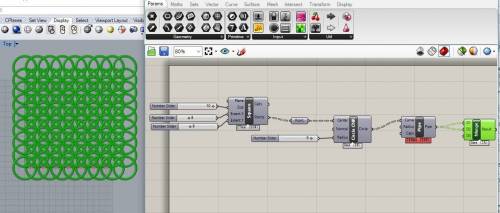

For the first design, in Grasshopper I created a square grid (via the Vector tab) using number sliders for the X and Y so that the grid can be adjusted to any size. I then used the points in the centre of each square as the starting point for a circle. I made the radius of the circles controllable using a number slider. I then used the pipe function to make the circles more solid.

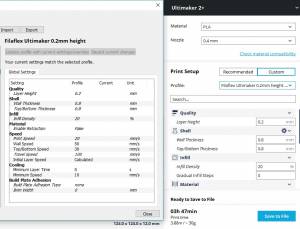

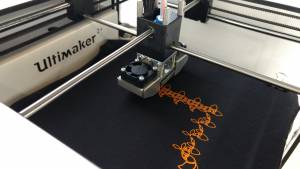

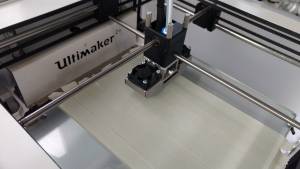

After this, I used the settings below in Cura (the program for slicing designs ready to be 3D printed) to print the design on fabric. I had to clip the fabric to the bedplate in order to keep the fabric stationary. I used a slower speed because the flexible filament needs more time to be extruded.

Second design

For the second design, I wanted to create a stand alone weave structure. Having no experience in Grasshopper, I needed to use a tutorial (http://www.grasshopper3d.com/video/defining-a-parametric-weave) to create a weave. The main steps of the tutorial are as follows:

- Select Square Grid (Vector tab), add number slider to the x and y directions - so that the size of the square grid (therefore the weave) can be adjusted

- Create a Cull Pattern (Sets tab, Sequence), with boolean toggle values (Params tab, Special) as input i.e. true or false, and link to a tree Branch (Sets tab, Tree) - in order to isolate different points to then manipulate separately (to create the up and down directions for a weave)

- Use Move (Transform tab, Euclidean) - to move a row of points up

- Use Vector Amplitude (Vector tab, Vector) with a number slider - to specify the height of points

- Use Flip Matrix (Sets tab, Tree) - to flip rows and columns to change the direction of the points (from y direction to x direction)

- Use Weave function (Sets tab, List) - to weave between 2 points, and using a boolean toggle to change the weaving pattern

- Use Interpolate Curve (Curve tab, Spline) and the weave function as the input - to create curved lines between points

- Cull again to isolate curves, i.e. the middle curve or the outer curves (of 3 curves)

- Use Rotate 3D (Transform tab, Euclidean) - to rotate outer curves

- Copy steps and switch true / false values - to create curves that are inverted/opposite to the original curves that form the basis for the up and down weave structure

- Use Pipe Component (Surface tab, Freeform) - to change lines (of the curves) into pipes, with a number slider to change thickness

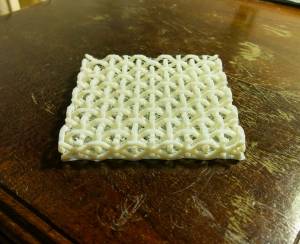

After I produced the weave using the tutorial, I adapted it slightly to experiment with a new design. The change I made to the original design was to mirror the design on top of itself - to create 2 layers of the weave structure. Printing this double structure with flexible filament, I was interested to see the results, how it would feel and what it would be like when pressed together.

I used the same settings in Cura as the previous print on fabric, however I encountered problems with the print. The first layers of the material were not sticking to the bed. I increased the temperature of the bed and also put down some sticky tape to help the layers stick better. The print improved, however, I still had problems. A colleague helped me with this problem by re-calibrating the height of the bedplate so that the nozzle would be closer to the bedplate. This solved the problem and the weave structure was printed successfully.

Final thoughts

It was useful to experience Grasshopper, however I found the program difficult use. It was hard to me to find the right function that I needed for a design element I had in mind, and to know what input the components required; often, the program produced results I didn't expect. I am aware that my first design is very simple, as I found it difficult to produce a more complicated structure that I wanted.

I am happy with the final products however. The flexible material makes them pleasing to touch and handle. The weave structure is flexible but also firm when pressed; this could perhaps be a useful structure to absorb the impact from movement.