Week 7: Textile as scaffold

This week, I produced a composite using layers of material with epoxy and catalysing solution, layered over a foam mould that I designed in Fusion 360 and milled it with the CNC milling machine, and then vacuumed it. To download the file for the mould, visit: https://oscircularfashion.herokuapp.com/project/-L6RF-fDdOQ_1MThYQ-t

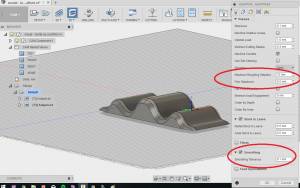

First of all, I created a shape in Fusion containing curves because I was interested in how the material would respond to the curves. I created a sketch, extruded it and rounded off the edges with the fillet tool.

In order to avoid any collisions with the drill tool, I had to ensure that the height of my model was less than 25mm, therefore I had to amend my design in Fusion and decrease its height.

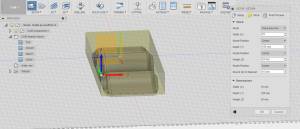

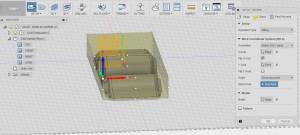

Once the design was final, I set up the model for CNC milling using the CAM workspace in Fusion:

- Unordered List Item I selected a drill bit and entered its dimensions into the software

- I specified a 'fine stepdown' of 0.5mm for a detailed finish

- I created a 'stock' (block of material) using the dimensions of my model, but adding 10mm to the width (x) and depth (y) to ensure the model would be contained inside

- I selected my 'zero point' - because my model was at a peculiar angle, I had to select the x and y axis orientation, and also flip the x axis

Once the mould was milled, I began the process of layering the materials with the epoxy mixture:

- I mixed a solution which contained 100g of catalyser and 30g of epoxy

- I put a thin layer of this mixture over the mould in order to protect the mould - this took a couple of hours to dry

- Once dry, I put a layer of foil over the mould and then sprayed some silicon to make sure the fabric wouldn't stick to the mould

- I then proceeded to fix 4 layers of fabric with the epoxy solution. The final layer of material also needed a layer of epoxy

- I placed a layer of plastic wrap over the model and then put it in the vacuuming machine for 30 minutes

After the model was vacuumed, I removed the composite from the mould and tidied up the edges using the sawing machine. Here is the final product:

Problems

The composite was a little difficult to remove from the mould - perhaps I didn't use enough silicon spray to separate the fabric from the mould. Also, the shine didn't work over the whole top of the composite - particularly in the parts that were depressed. Perhaps making a negative mould to press all the parts evenly would have fixed this problem.

Final thoughts

I was surprised and pleased by the strength of the final composite and the fabric took the curves of the mould well. When sawing the edges of the composite, the material was less hard - I realised that I needed to use more epoxy solution at the ends.