PLACE : Wemake Milano

DATE: 4/10

PEOPLE: Zoe, Luisa, Francesco, Giorgia

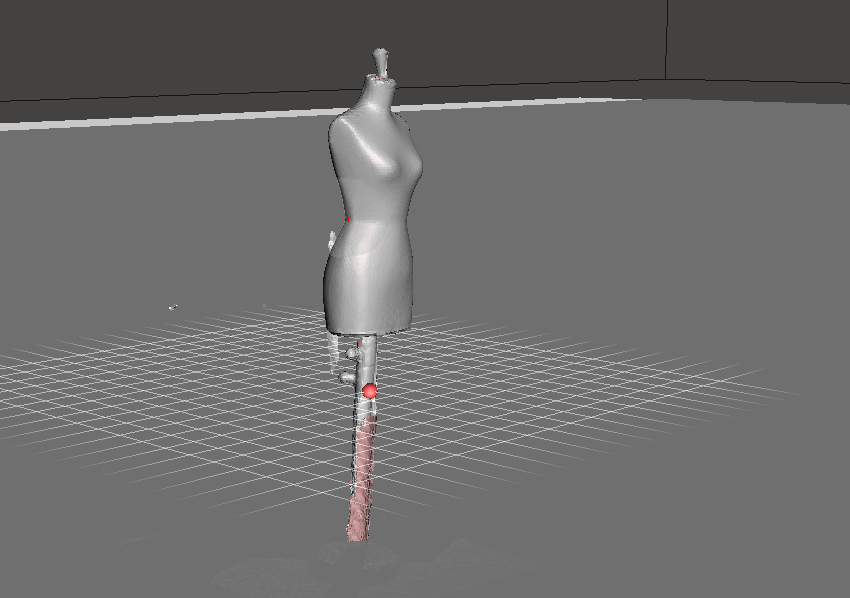

STEP 1

SOFTWARE: we used Skanect + Kinect to scan our bodies. Finally we decided to scan a half-mannequin to have a cleaner file.

ISSUES: be sure to scan carefully the whole object!

NOTES: next time we do our bodies! Keep about 1m distance from the scanned object: blue: too far, green: good, yellow-to-red: too near

FILES: You can download the files here.

STEP 2

SOFTWARE: We used Autodesk Meshmixer to clean the file of the scanned mannequin.

ISSUES: place the point of symmetry in the right place!

NOTES: useful tools are simmetry, autorepair, smooth fill

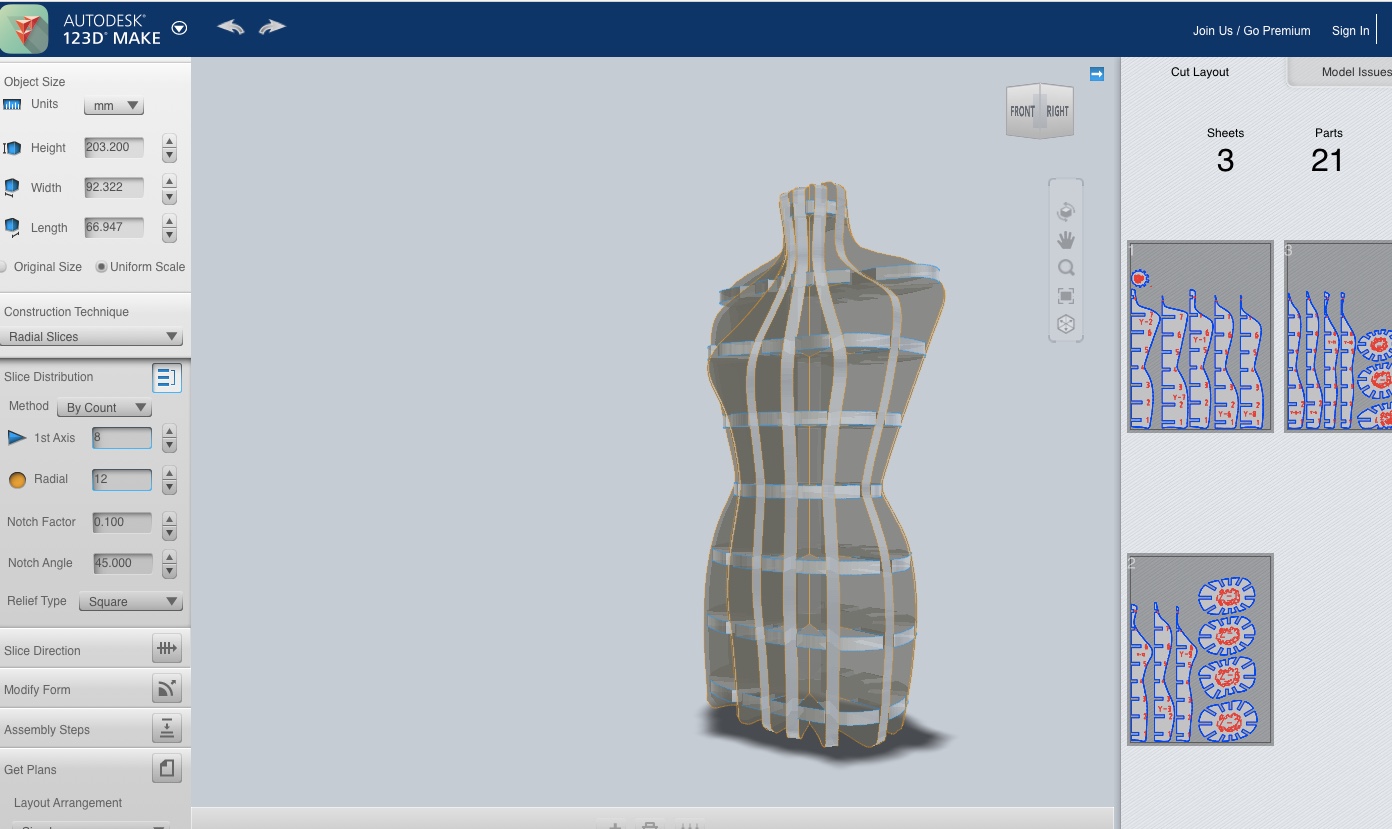

STEP 3

SOFTWARE: we used 123D Make to slice the model. It produces files of the pieces with numbers to facilitate the assembly. However we couldn't export the files to laser cut and therefore in the end we use Autodesk Fusion 360 Slicer

ISSUES: we made 20 vertical slices and about 20 horizontal: they seem to be too many to assembly the mannequin. 10 -15 vertical and 1-3 horizontal pieces should be enough.

NOTES: check carefully the thickness of the material that you want to laser cut and leave a few millimetres of margin. Check the dimension of the object.

STEP 4

MACHINE: laser cutter with 6 mm cardboard

ISSUES: 1 piece was not cut, 2 pieces were correct but smaller

NOTES: consider 1 hour to cut and check all the pieces before assembly

STEP 5

TOOLS: hands and muscles

ISSUES:too many pieces, some cardboard slices bended

NOTES: as soon as our laser cutter is working, cut the 3 missing parts. Promised.