PLACE : Wemake, Milan

DATE: 18/10

PEOPLE: Cristina, Giorgia, Luisa, Zoe

BIODYES

STEP 1

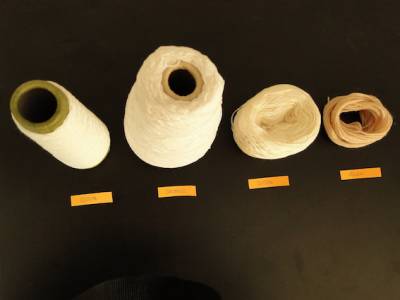

MATERIAL: We chose to use hibiscus dried flowers and curcuma powder to produce violet and yellow dyes. We had a variety of natural animal (wool, silk) and vegetal (cotton) tissues to test.

Where to buy material?

- hibiscus: herbalist's shop

- curcuma: supermarket

- alum (mordant): pharmacy

CREDITS: We used the recipes from Textilabs Amsterdam. All photos from Luisa Valente.

NOTES: an easy way to identify the origin of a fiber is to burn a small piece of tissue and smell it

- artificial fibers: black smoke and become hard

- animal fibers: disgusting smell similar to burned chicken skin

- vegetal fibers: almost no smell

STEP 2

PROCESS: Plese refer to the link above for the recipes and the detailed instructions. To summarise, the steps of the process are the following

- weight the dry fibers to calculate the amount of mordants to add

- wash your fibers. The process is different if the fibers are vegetal (add soda: 6% of the fiber weight) or animal.

- mordant the fibers: we used alum (10-15% of the fiber weight)

- extract the dye

- bath the fibers in the dye (50 degrees for animal fibers and 80 for vegetal for 1 hour at least)

- add the modifier (option) to change colors

- rinse

- dry

ISSUES: we didn't have a thermometer and therefore it hasn't been easy to control the bath temperature.

NOTES: animal and vegetal fibers need to be prepared in different ways!

STEP 3

RESULTS: We obtained beautiful yellow and pink fabrics, the nuances depending on:

- kind of fiber

- modifier (yes or no)

- knots (to create patterns)

We are especially happy with the dying of wool and cotton. Unfortunately silk texture lost its typical shine.

ISSUES: some of the fibers dyed with hibiscus lost color once dried. We believe that 1 hour bath is not enough to keep the colors vivid, at least for hibiscus. Time allowing, we should have tested 4 hours or even all night baths.

NOTES: you need time to work on natural dyes. What about washing them? To be researched… Next time we would like to experiment with the shibori too.

BIOPLASTICS

STEP 1

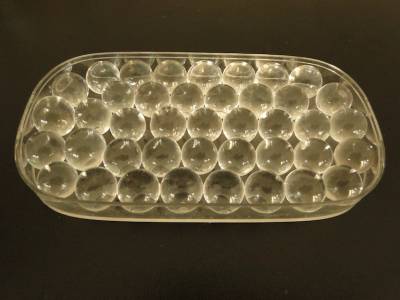

MATERIAL: We had plenty of material to mix with the bioplastic: grains, seeds, powder, flowers, hydrogel spheres…

Where to buy material?

- gelatin powder: supermarket

- glycerol: Amazon

CREDITS: We used the recipes and instructions from the booklet The Secrets of Bioplastic by Clara Davis, Fab Lab Barcelona. All photos from Luisa Valente.

STEP 2

PROCESS: Plese refer to the link above for the recipes and the detailed instructions. To summarize, the steps of the process are the following

- Mix the cold water and the gelatin powder in the pan without heating

- Heat the preparation while stirring slowly so that there are no lumps

- Once the preparation has become liquid and homogeneous add the glycerin into the mixture

- Pour your mixture into the mold or the prepared surface

ISSUES:

- pour a thin layer of the gelatin mix into the mold before adding the material that you want to incorporate and then cover it completely. This will ensure a homogenous external layer of bioplastic

NOTES:

- we didn't have much foam as expected from the Clara Davis' instructions.

- use a plastic or glass mold (no paper)

- you can play with glycerol to have softer or harder bioplastic

STEP 3

RESULTS: We obtained beautiful semispheres and other shapes with grains and hydrogel that could be used for expos and decorations. We are especially happy with the saffron mix because of its texture and color.

ISSUES: as we didn't have enough gelatin powder, we decided to replace it with starch but we ended up with a whitish soft gel that we didn't like at all. It might well be that we added too much starch but in the end we bought more gelatin powder to continue the testing.

After a couple of days, the bioplastics were covered by mould. It is possible to remove it with a sponge and let the plastic dry at the sun. To avoid the moulding, it's useful to rub lemon, vinegar or alcool on the plastics and let them dry in a warm and dry place.

NOTES: we would like to experiment with laser cut laces structures and pour a thick layer of gelatin mix on it to produce flexible but solid bioplastic sheets.