This is an old revision of the document!

Bootcamp Paris 2017 - Romain Di Vozzo

After this very interesting first day of Fabricademy, I wanted to bring together what we learnt with our chain of design and production at Fablab Digiscope. For this 1st day assignment, I used Illustrator CS5, Corel Draw 6, and an Epilog laser-cutter Mini Legend 40W. The material I cut was 3mm thick natural leather. I had bought the leather from La Réserve des Arts (https://www.lareservedesarts.org/catalogue/).

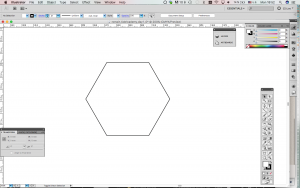

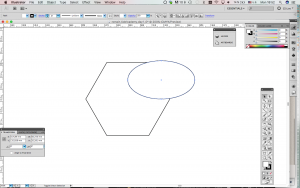

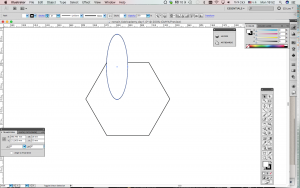

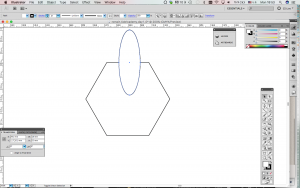

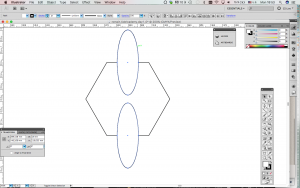

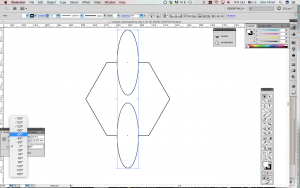

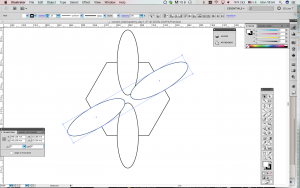

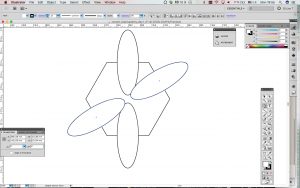

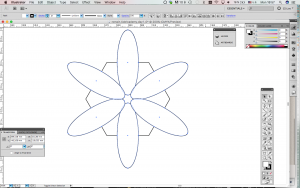

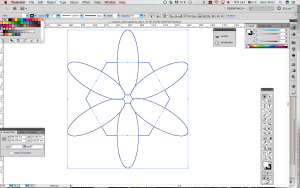

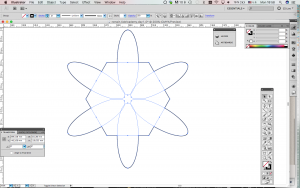

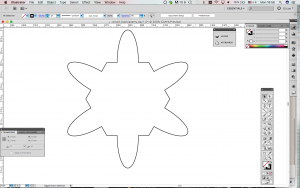

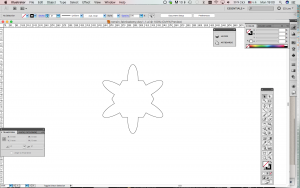

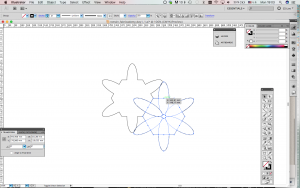

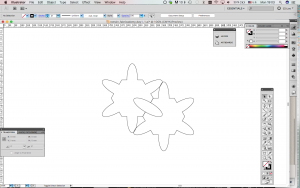

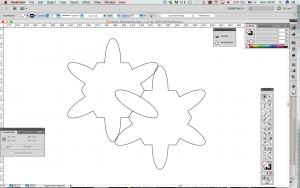

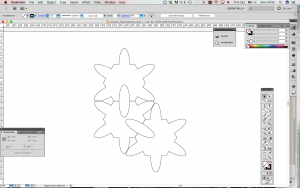

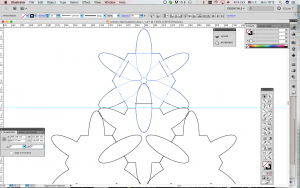

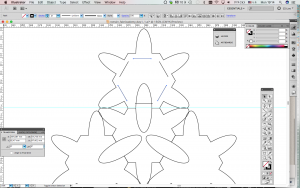

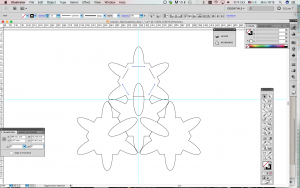

01-Designing a modular pattern to be laser-cut and assembled instantly

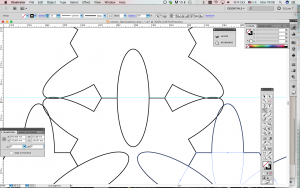

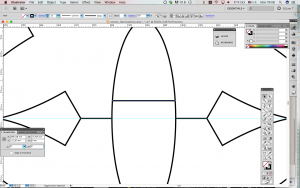

Here I have created a pattern from scratch in the vector software Illustrator (commercial). It is a polygon assembled with ellipses I would later join together. The idea is to conceive them so that they can fit one next to the other, and some small elliptical extensions coming out from each polygon/modules will feet into small gaps of the other polygon/modules around. When the design was done, I exported it as a .pdf file. That's what our laser-cutter likes best.

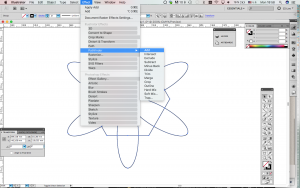

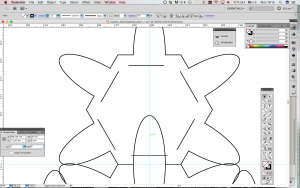

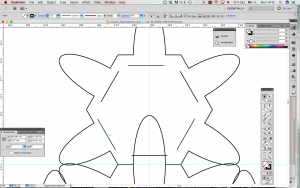

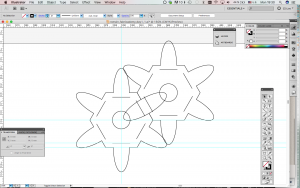

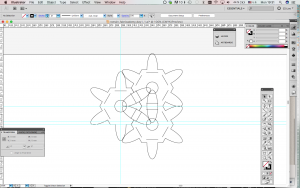

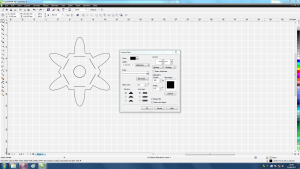

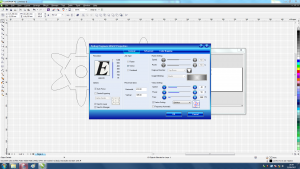

02- Preparing polygon/modules to talk to the laser-cutter with Corel Draw 6.

First I have converted the outline of my polygon/modules to “hairline”. Then I entered the parameters to cut leather according to the Epilog Book. They were wrong. I had to cut the same file 4-5 times. It varies a lot with the type of leather itself.

03- Placing the 3mm thick leather in the laser-cutter.

Leather is organic so it never really is flat.

video to come