This is an old revision of the document!

Week 11. Soft Robotics

Global Instructor - Lily Chambers

Program Outline

This class will focus in the study of a specific field in robotics, the soft robotics. Unlike rigid robots we are mostly used to, soft bodied robots have similarities and performance characteristics similar to living organisms or the human body. Soft-robotics are based in Bio-inspired design or biomimicry and have applications in wearables, rehabilitation prosthetics, surgical robots, rescuing and others. We will focus on the fabrication of soft actuators, sensors and grippers using novel materials, artificial muscles and performative locomotion design.

References

Biomimicry

Locomotion

Pneumatics

Flexures

Molding and casting

Assignment:

Level BASIC: Pneumatic wrist brace

Level Intermediate: Soft Gripper

Level Advanced : Pneumatic, digitally controlled system

Hands On

Constructing a Soft Gripper

I consider myself as a basic level in Soft Robotics, but I was tempt to make the Soft Gripper, but in a way to explore more the possibilities of the silicone, than 3D printing, because I've thought on those people that perhaps will not have the 3D printer close to them, so I search for a gripper project without 3D printing, and I've found this one that I replicated.

https://www.youtube.com/watch?v=uPx8xwRpfFk

https://www.instructables.com/id/Soft-Robotic-Grabber-No-3D-Printer-Required/

01. Materials

For the Mold:

Cardboard (about two square feet)

Box Cutter

Cutting Board

Hot Glue Gun

Scotch Tape

Gloves (latex free)

Robot:

Smooth On Ecoflex 00-30

Scissors

Printer paper

Nail

Soda/water bottle with lid (at least one liter)

1/8 in OD pneumatic tubing

Curling ribbon

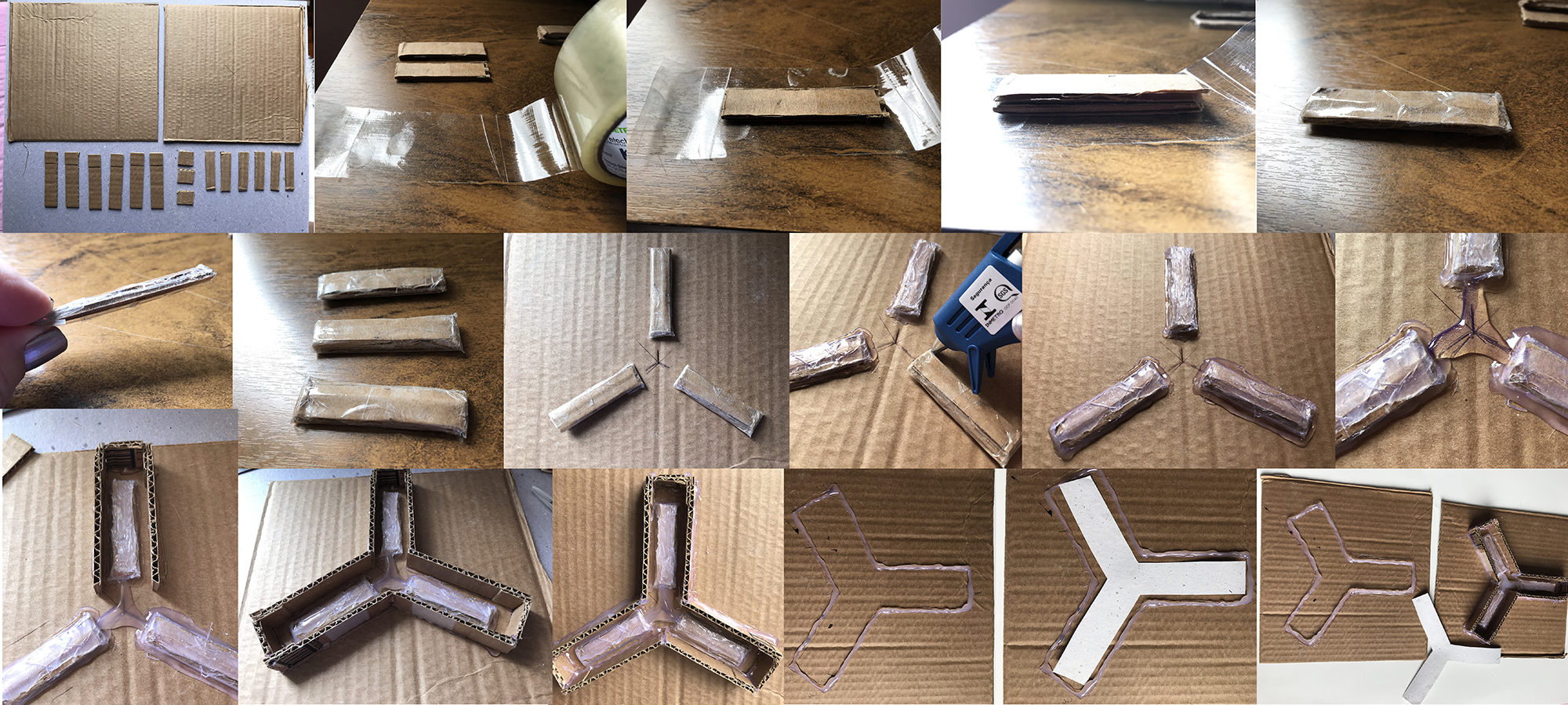

02. Constructing the Mold

a. Cut the cardboard

6 pieces 6,3 x 1,3 cm

6 pieces 8,9 x 1,9 cm

3 pieces 2,5 x 1,9 cm

2 pieces 23 x 23 cm

b. Mounting the mold

Wrap the each two pieces from 6,3 x 1,3 cm together with the tape.

In one of the 23×23 cm cardboard draw the center and 3 legs separated between 60 degrees from each other.

Put them in the right position as in the image, forming the 3 legs separated by a 60 degres from each other, and distance of 2 cm from the center of the figure.

Glue everything in the position with the Hot Glue Pistol.

Make the conection from one leg to another with HotGlue, so it will be the link between the three air spaces when ready.

Put the 8,9 x 1,9 cm pieces like the walls from the mold, and close the end of each part with the 2,5 x 1,9 cm pieces, everything glued with HotGlue.

In the other 23x23cm board draw the contour of the mold constructed, and make a small wall in this draw with the HotGlue.

Cut a piece of print paper with the draw and dimensions of the interior of the Mold.

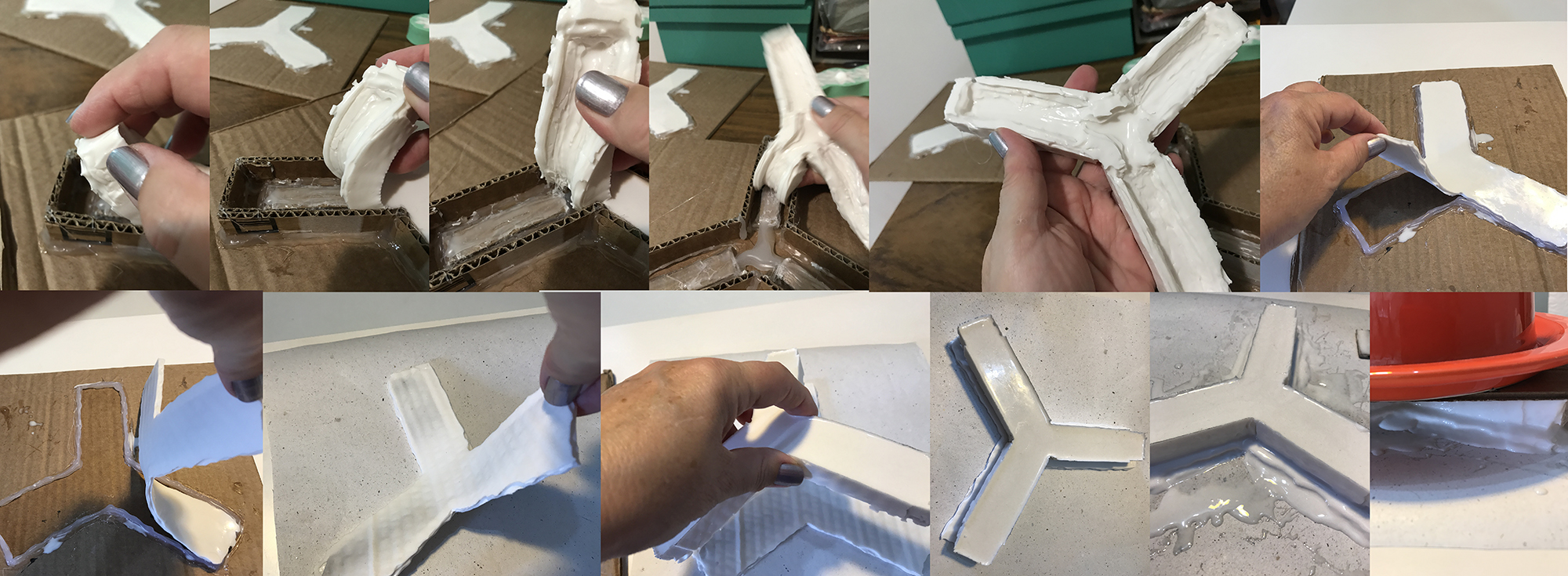

b. Filling the mold

Prepare the Silicone Rubber, mixing the catalizer With the silicone rubber solution in the proportion indicate for the manufacturer.

Stir gently with a stick so as not to bubles.

Pour the solution into the mold until you have a thickness for about 3mm above the air chamber.

In the mold B (for the basis) pour a thin layer very well distributed , than put the paper cut in the correct format, and another layer above.

Wait four hours to solidify or polymerize

c. Joining the two pieces and installing the air system

After 4 hours, verify if the silicone is already polimerized, dried and like a rubber.

Remove the pieces gently from the Mold and put the basis over another cardboard and the piece A over it.

Join the two pieces with another fresh bath of Silicone Solution prepared with the catalyzer.

Be sure that every space between the two pieces is very well connected and take care to fix any imperfections.

Let it dry and polymerize for at least 4 hours.