This is an old revision of the document!

Week 11: Soft robotics

This week I designed and 3D printed a mould similar to the soft gripper mould in the presentation, which I used to create a soft gripper out of silicone rubber. I inflated the gripper and

The Process

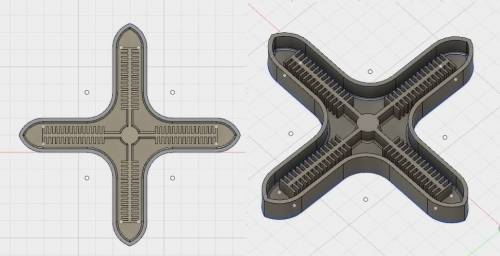

I used the design shown in the presentation to create a mould in Fusion 360 that had rounded corners at the centre and pointier ends on the arms. I thought that the rounded corners might make it easier to remove from the mould and decrease the likelihood of tearing. I then 3D printed the mould using normal PLA.

To create the soft gripper, we gathered together the needed equipment - a receptacle, a stirrer, gloves, weighing scales, a flat plate, our moulds and Ecoflex part A and Ecoflex Part B. We mixed part A and part B in a ratio of 50:50 and stirred for 2 minutes.

I then poured the mixture slowly into my mould, trying to make sure the surface was even. I waited for the mixture to settle for 5 minutes to let any bubbles settle. After this, there were still bubbles in the mixture, therefore I tried to use the stirrer to pop any bubbles.

As well as the mould, it was necessary to create a flat silicone layer to be placed over the top of the gripper in order to seal it. For this, I poured the Ecoflex mixture onto a flat plate with a thickness of a few milimeters.

I placed both the mould and the plate into the oven at 70 degrees for 15 mins in order to speed up the drying process. Once out of the oven, I tried to remove my gripper from the mould. However, the gripper was very stuck to the mould and it tore and came off in pieces. I assume this was because the ratio of Ecoflex wasn't exactly 50:50, perhaps due to a human error or the weighing scales were faulty.

I repeated the process above again to produce a second gripper. When this one came out of the oven, it was much better and easier to remove. It was still a bit stuck and I had to be careful not to tear it.

To stick the flat layer onto the gripper, I used more of the Ecoflex mixture - this time to act as glue. I spread a thin layer over the flat piece and left it for 2 minutes to settle. I then put the gripper face down onto the layer - so that the air chambers were covered. I put a bit more Ecoflex around the perimeter of the entire mould to secure it.

I then put this in the oven to dry out the Ecoflex and secure the pieces together. Once out of the oven, I used scissors to cut the gripper away from the excess flat layer.