This is an old revision of the document!

Final Project: E-textile & Wearables application for ParaRowing Olympic Athletes

(25/01/2018)

My motivation: ParaRowing Olympic Athletes :fabricademy2017:students:detoledomotta.naiadelara:rowingmain2.jpg?nolink&430x183

The problem: Difficulty of arbitration and damaging current straps.

The idea: A E-textile vest coupled with back support :fabricademy2017:students:detoledomotta.naiadelara:28.png?nolink&200x218

- Back Support: The Idea for a back support comes from the fact that by offering

- E-textile application:

- How should it work:

-

What I did: Step-by-step production

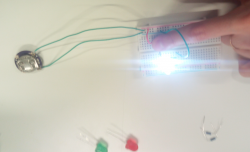

- STEP 1: Research for inspiration of back supports and build electric circuit.

During this first step I did a research on back supports for upper back that already existed and fit my purpose and also make with breadboard, cables and a button for the touching function.

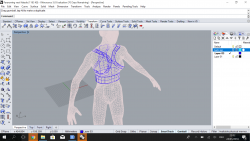

- STEP 2: Design in Rhino of the vest and electric system that should be couped with vest and grasshopper for the different patterns for back support

THE VEST: In this step things got a little more complicated with the software designs but after finding an inspiration I designed in Rhino using the 3D body model with had for dimensions. But using different layers and the previous experience with Rhino helped to shorten time.

THE VEST: In this step things got a little more complicated with the software designs but after finding an inspiration I designed in Rhino using the 3D body model with had for dimensions. But using different layers and the previous experience with Rhino helped to shorten time.

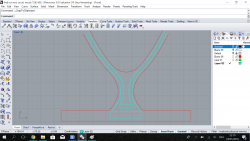

THE CIRCUIT: After dimensioning it I transformed from 3D to 2D made some arrangements and created the electric system in a different layer based on this 2D design of the vest. This step was necessary for the laser cutter, since I knew I waned to use it for cutting different e-textiles and testing with them.

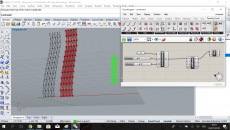

THE BACK SUPPORT: For the back support I decided to apply the knowledge acquired during the textile as scaffold week, where I used wood to make a back protector. This experience made me very confident that this technique would work. Therefore using the grasshopper function of rhino to design different patterns.

THE BACK SUPPORT: For the back support I decided to apply the knowledge acquired during the textile as scaffold week, where I used wood to make a back protector. This experience made me very confident that this technique would work. Therefore using the grasshopper function of rhino to design different patterns.

-

- STEP 3: Cutting and testing with different materials

This was the most fun part of the process and thanks to the laser cutter and rhino files I could cut the vest and the circuit using different materials to test their level of accuracy and chose the final one for the first prototype.

THE VEST

: For the vest I waned to test different textiles resistance and flexibility. Therefore cut the vest in the laser cutter in 5 different materials.

: For the vest I waned to test different textiles resistance and flexibility. Therefore cut the vest in the laser cutter in 5 different materials.

THE CIRCUIT: Same idea as for the vest but with conducting textiles. For this step I selected 3 different materials and tested their accuracy with stretching and water resistance.

At the end I chose two combination of textiles for the vest coupled with the conductive path. Voltmeter was used for measuring conductivity.

The conclusion I have made by testing drove me into thinking a not so stretchy textile should be used as base for the circuit.

THE BACK SUPPORT: Still with the same inspiration of different materials I used the laser cutter for two different materials: Acrylic and Wood

.

- STEP 4: Assembly - First Prototype finished

.

.

.

.

.

.

.

.

.

.

.

.

.

.

- STEP 5. Improvements - Second Prototype

What changed

Further suggestions of improvement:

Fabricademy knowledge applied at the end

Back support - Textile as scaffold and a lot of grasshopper design for different pattern ideas and use of laser cutter for production.

Circuit - E-textile experiments with conductibility, stretch levels and water and silicon resistance.