Soft Robotics

Program Outline

This class will focus in the study of a specific field in robotics, the soft robotics. Unlike rigid robots we are mostly used to, soft bodied robots have similarities and performance characteristics similar to living organisms or the human body. Soft-robotics are based in Bio-inspired design or biomimicry and have applications in wearables, rehabilitation prosthetics, surgical robots, rescuing and others. We will focus on the fabrication of soft actuators, sensors and grippers using novel materials, artificial muscles and performative locomotion design.

References

- Biomimicry

- Locomotion

- Pneumatics

- Flexures

- Molding and casting

Assignment:

- Level BASIC: Pneumatic wrist brace

- Level Intermediate: Soft Gripper

- Level Advanced : Pneumatic, digitally controlled system

Files

All the files created for this assignment can be downloaded by clicking on the link bellow:

Designing a Soft Gripper Mold

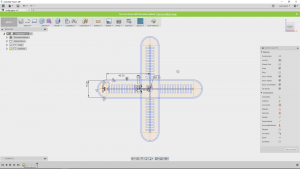

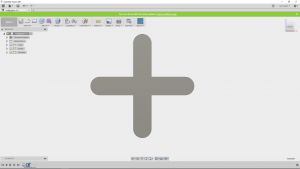

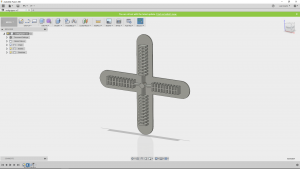

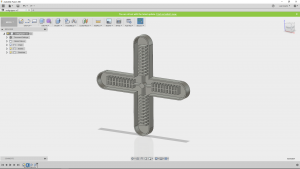

The design of the mold was done on fusion 360. In general, I created a sketch for the whole mold and then made three extrusion with different lengths, so I extruded out only the base of the mold towards the back face, then, I extrude out toward the front face the inner parts of the mold and, finally, I extrude out the walls of the mold towards the front face.

The body was exported as an STL file.

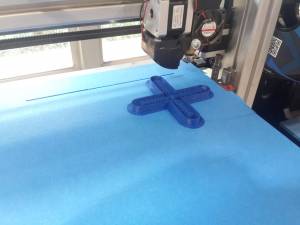

Printing the Mold

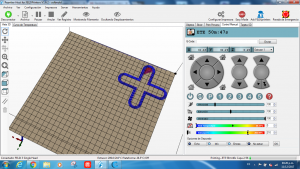

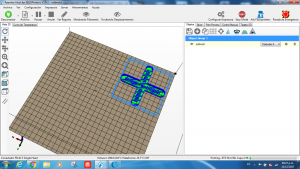

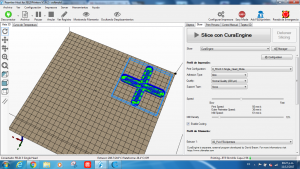

For printing the mold I used a Felix printer. In general, I imported the stl file into the Repetier software; then, I added a brim layer to the body and did not added supports, the parameters were configure for printing with PLA.

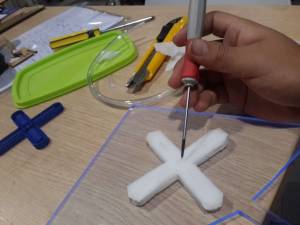

Casting the Mold

First, I mixed silicon with its catalizer in a proportion of 3% of the silicon weight, I did this with the aid of a balance; then I poured the mix into the mold and waited until it got dry; once it was dry, I took off the the silicon griper from the mold; after that, I prepared a new mix of silicon and catalizer and pured this mix over an acrylic board, so that it formed a thin layer; then, I put the silicon gripper over the thin silicon layer so that it closed the top part of the silicon gripper; I waited until it was dry and made a hole to it for inserting air. At this point, I tested the gripper and realized that the thin layer was too thin and had a hole so I added another thin layer again. So I tested the gripper again but because of the hardness of the silicon it did not move at all.