Table of Contents

Class 2 : Digital Bodies

FIRST MODEL - My Cardboard 3Dbody with App Android Smartphone SCANN 3D

Project Description

Scan my body in 3D to create a model bust on my measurements.

Inspirations & References

Techniques

- 3D Scanning

- 3D Modeling

- Laser cutting

Materiel

- computer Asus Notebook PC UX410U

- Cardboard3mm 10OOX700mm

Tools

- App Android Smartphone SCANN 3D

- Fusion360

- NettFabb

- Slicer

- Coreldraw

- Photo Repar

- laser Fusion M240 Epilog - 1 016 x 711 mm

Fichiers

1/ PHOTOS SCANNING OF MY BODY WITH SCANN3D APP

Move around the objet

To make a good model? Follow a circular path and stop when taking pictures. You need to move the device itself, it is insufficient to move the target object. And Obviously, you need someone else's help to take the pictures.

3D object quality

An environment with a net fund and you must take the time to stop for each photo every 40cm around the body.

I take 20 pictures and the result is pretty fine with bark details, shadows and light on tree.

you can click once and twice on it to see the animated Gif.

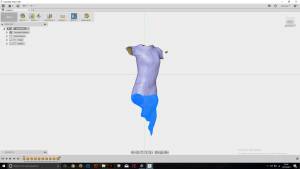

2/360° FUSION 3D SCAN MODELING OF MY BODY

preparation of the 3D model, cutting, closing, cleaning,

Application Android Scan3D The export is possible in .stl, .ply, .obj, .pcd.

I test Fusion 360 for the first time, it's difficult to understand how the object can be moved in the 3D space - So I try several possibilities -

First, you have to go in nav bar on insert > insert mesh to import your 3D Scan in .stl.

Then, you can select parts of the object and in the nav bar on Modify > Remesh it to smooth the surface.

I was just trying to keep the bust and not the head, the arms and the lower body. So I selected all the parts that I wanted to delete. (clic on suppr button).

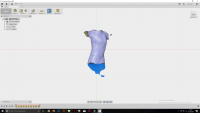

3/ NETFABB 3D SCAN MODELING OF MY BODY

but my object was empty and Slicer Autocade couldn't work on an empty form so I kept the entire object. I decided to try netFabb. I could selected and cut a part keeping my object full.

You can move your cut line with 3 axes (in blue on the screen picture).

Vision of the back body, the blue slice is positioned so as not to cut also a part of the hip.

On the left, in the context frame, select: Cut all part and right click on the sphere icon. You select the part and delete it. the orange part is the selected area will be deleted.

Vision of the back body, the green edge is positioned to cut the bottom of the pelvis along the y-axis.

The Rotate Parts menu allows you to configure the rotation of the 3D object in space according to the x, y, z axis. Here, you can see different parameters to move you object and rotate it.

The object must be positioned straight along the axes so that it can then be cut into perpendicular slices on the ground.

Export the file in. stl to open it under Slicer.

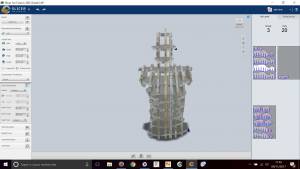

4/ SLICING OF MY BODY WITH SLICER

Slicer Settings

- CUSTOM MANUFACTURING SETTINGS

- Interlocked units mm

- length : 1016mm

- Width : 711mm Thickness : 11,5

- No margin

- slot Offset : 0,010

- Tool diameter : 0

- OBJECT SIZE

- units : mm

- Height : 710mm

- Width : 349,794mm

- Length : 235,366mm

- INTERLOCKED SLICES Method by distance

- 1 st Axis : 4,795

- 2nd axis : 2,089 Notch

- Factor : 0,100

- Notch angles : 45,000

- Relief Type : square

I Import my object in Slicer (Carrefull, you have to choose your axe before open it for have you object in the right sense = Top and Down)

you can see on the right, the cut is in red = this informs me of a problem, the size of the model is too big for the support.

I modified the size of my object for have the entire object in the final support.

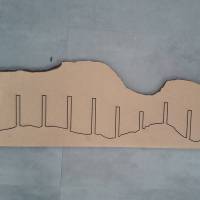

the final object appealed to me, especially the side section which made it possible to see the different layers drawn. Aesthetically it was interesting but I wondered how I was going to make him stand up and be able to dress him…

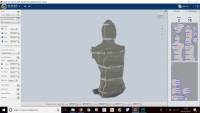

5/ SLICING 3D MODEL OF MY BUST WITH SLICER

settings Manufacturing

personal options

I tried the curve construction technique by count and add a curve number. You can add or delete slices.

a curved line with several anchoring points on the body allows the slices to move precisely.

in curve with custom slice distribution, you can add or delete and move slices.

I tried the Interlicked Slices construction technique by distance.

Customize Manufacturing Settings

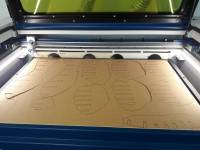

This mode allows you to adjust the bottom of the cut layout to the dimensions of the laser Fusion M2 d'Epilog.

6/ IMPORT THE 2D BUST FILE IN CORELDRAW

In the upper left hand corner, choose from the drop-down menu The laser cutter that suits your cutting needs.

Open the. pdf document.

Select the lines to be cut and choose the width: Hairline option from the outline pen drop-down menu. Hairline lines are configured to be cut.

Choose the option Print or Ctrl + P Go to preferences

Epilog LAser cut Settings

- Default Settings : CO2

- Auto-focus : on

- Thickness : 11mm

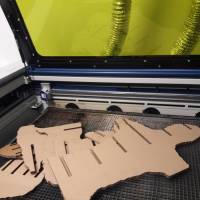

LASER CUT

USE THE EPILOG MACHINE TO CUT SLICES OF MY BUST

Safety tips for wood

Certain precautions must be taken when using the laser cutter.

Especially in the case of wood cutting, to avoid fire, the aerator and air compressor are activated.

laser Fusion M240 Epilog - 1 016 x 711 mm with Joystick Controls

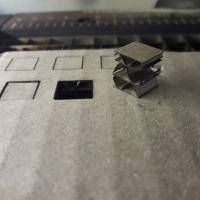

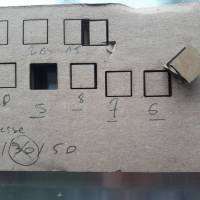

tests laser cut settings

1/ Import the document into coreldraw

2/Open a new window to perform cutting tests on the material

The test is carried out first on a small piece of the support to try out several settings and cutting parameters.

3/Distribute cut-outs so that as little material as possible is wasted

4/check if the cutting support is the right one

5/validate the zero with the control joystick

6/apply cutting parameters and start cutting

for this model, it takes 3 passes.

The cardboard can ignite with the air call if the cut-out is too close to the edge.

7/see if all the parts are cut out properl.

MOUNT THE STRUCTURE

ASSEMBLY OF THE 3D BUST IN CARDBOARD SLICES

1/ Follow Slicer's assembly model

Improvements and Challenges

When cutting the first bust, during assembly, the boards didn't overlap to the end. the dimensions related to the thickness of the cardboard under Slicer did not correspond to those of the print.

The second cut had the right settings even if it would still require some adjustments, the supports move and some small pieces fall easily.

Clic on the red link to see the documentation of the final cardboard bust :

Final 3D Scan with 3D laser scanner

Final 3D Scan with 3D laser scanner