Class 2 : Digital Bodies

My Cardboard 3Dbody with 3D Laser Scanner

Technics

- 3D Laser Scanner

- 3D Modeling

- Laser cutting

Materiel

- Cardboard3mm - 1000X700mm

- cutter

Tools

- 3D laser scanner Konica Milolta - technical specifications Link

- NettFabb

- Meshlab

- ZBrush

- Slicer

- Illustrator

- Coreldraw

Assignement Project Description

Use software to obtain a body-figure and a digital fabrication process to produce it (the production happens in groups of 3-4)

Use a 3D Laser Scanner as part of students' practical work in order to obtain a better rendering of the 3D object.

Inspirations & References

Clic on the red link to see the documentation of the first cardboard bust tests:

First 3D Scan with Smartphone App

First 3D Scan with Smartphone App

1/ PHOTOS SCANNING OF MY BODY WITH 3D LASER SCANNER KONICA MINOLTA

The living model must move as little as possible. Close your eyes for the scanner beam. Favour light clothing that attracts light.

2/ ASSEMBLY OF THE DIFFERENT SCAN LAYERS ON THE PROPRIETARY LASER SCANNER SOFTWARE

This step is quite tedious and the longer the scan takes, the longer the 3D object will take. The 3D laser scanner does not locate the front of the object's backside, so it must be given precise reference points to add the slaps between them.

3/ 3D BODY OBJECT CLEAN AND REPARE WITH NETFABB

preparation of the 3D model, cutting, closing, cleaning,

4/ 3D BODY OBJECT CLEAN WITH TOOL BRUSH SELECTION ON NETFABB

5/ 3D BODY FILES CONVERSION .stl in .obj WITH MESHLAB

6/ 3D BODY OBJECT SMOOTHING WITH Z BRUSH

7/ 3D BODY OBJECT MENSURATIONS WITH 123dDesign

8/ 3D BODY WITH SLICER

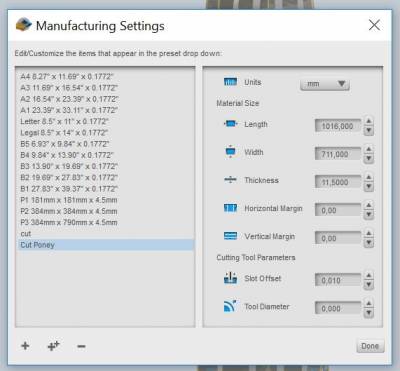

9/ MANUFACTURING SETTINGS 3D BODY WITH SLICER

10/ IMPORT 2D PLAN

11/ ADDITION OF A CENTRAL CUT-OUT TO SLIDE A BUST SUPPORT FOR THE BUST WITH ILLUSTRATOR

12/ LASER CUT PARAMETERS WITH CORELDRAW

LASER CUT

1/ USE THE EPILOG MACHINE TO CUT SLICES OF MY BUST

MOUNT THE STRUCTURE

1/ ASSEMBLY OF THE 3D BUST IN CARDBOARD SLICES

Improvements and Challenges

The difference in precision is important between the 3D scan app and 3D laser scan.

Processing the 3D image takes a long time (about 10 hours).

The rendering corresponds to my expectations, the dimensions correspond to a few centimetres ready.

The next protoypes will have access to a search for custom busts production. Test the paid version of Scan 3D APP.