Detailed Documentation Week 7

Exercise:

This week is about creating a tool (hardware) when the current tools are either not working to your liking or not existing yet. Our machine of choice is the CNC milling machine, of which we want to make a gigantic embroidery machine. We decided to work on this assignment as a group, since it is quite a lot of work and split all the tasks between the students. Me and Julia got to make the frame holder.

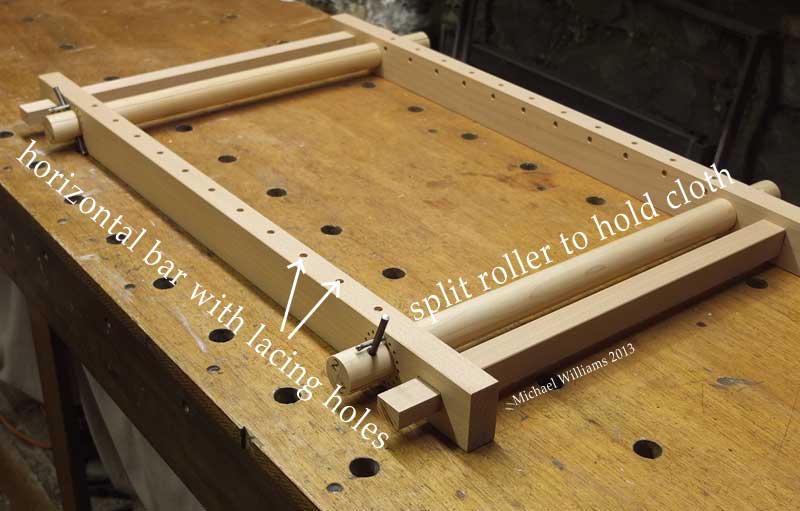

Inspiration:

We wanted to create a similar way of holding the fabric, yet get rid of the 'stiffness' of the frame. As in: the frame on the picture can only be used in one way. For our embroidery machine it needs to be possible to put different sizes of fabric in the machine.

Process:

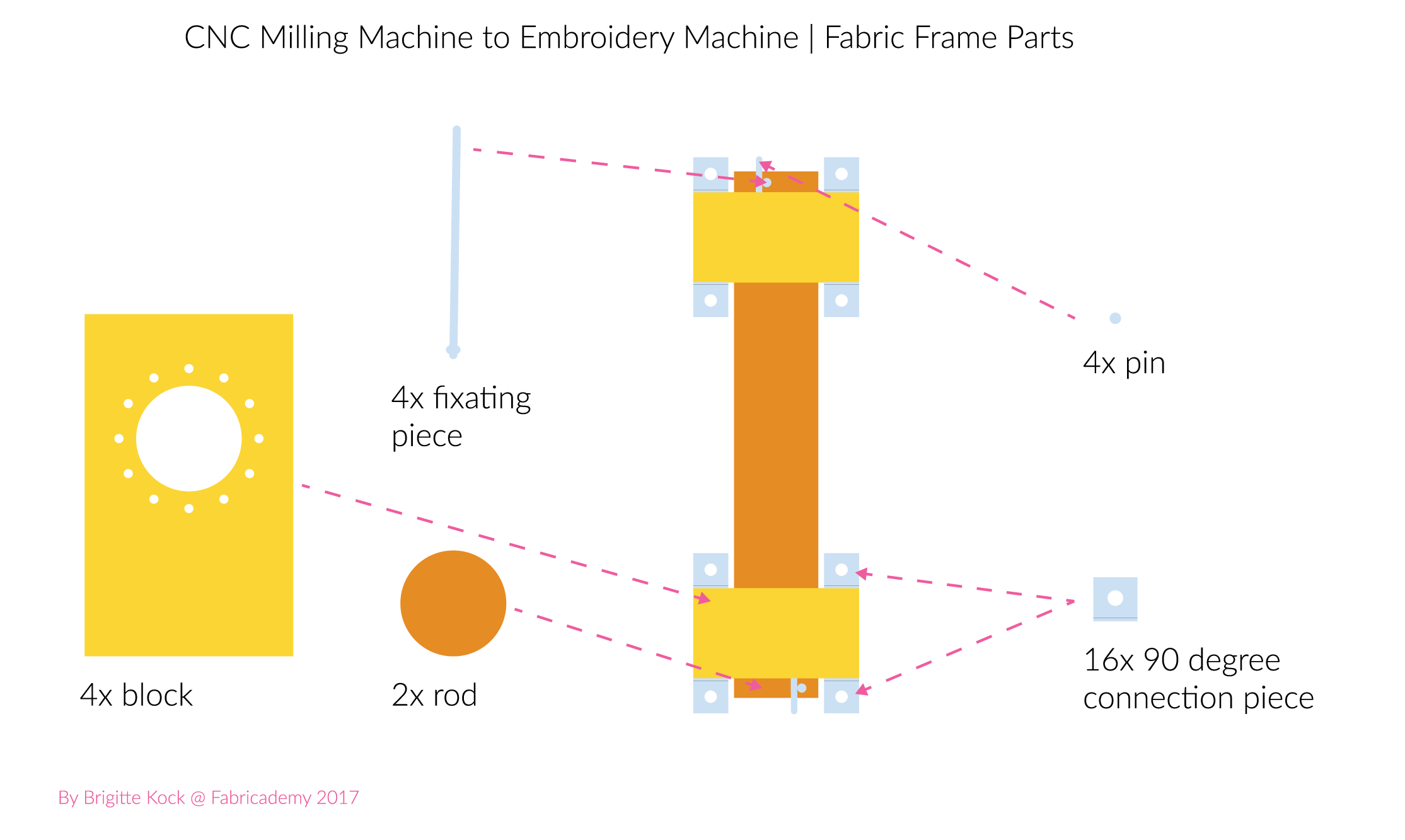

For the making of the fabric holders you need:

- 4x block with small holes around the hole where the rod goes through

- 16x 90 degree angle connecting pieces

- 2x wooden rod (1350mm) with a diameter of 32mm

- 4x pins (to hold the rod in position)

- 4x fixating piece (to turn the rod and thus tightens the fabric)

- 4x ending for the fixating piece

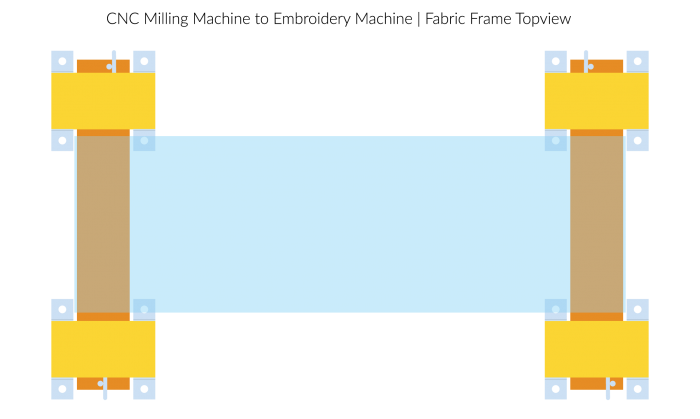

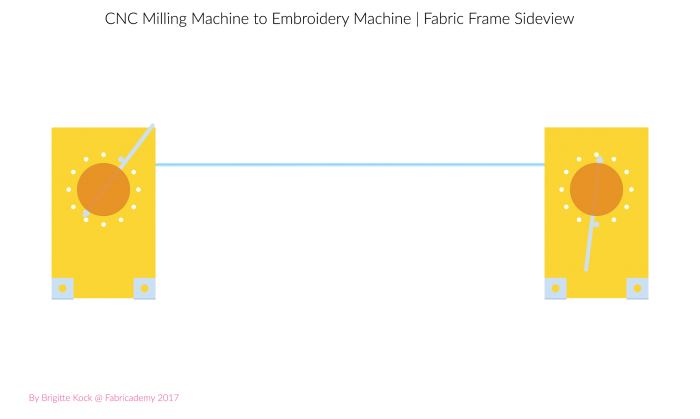

Here you can see how (simplified) the system is supposed to work:

Being a Maker:

This week I realised for the first time what it means to be a 'maker'. It's a very different way of creating objects then that I have been taught. Firstly it is about making it work, secondly it is about speed. Whether it is original, scalable, innovative, aesthetic is all of second importance. Where I would spend a week thinking about how to get to making an innovative frame; what is on the market now?, what type of fabrics need to go in?, how can we make it a multi-usable as possible?. All the time I had spent thinking and designing, was all the time it took to make the whole machine.

This week showed me big scale rapid prototyping that I've had never experienced before.