Textile as Scaffold

This week's assignment was to experiment with different techniques while using textiles as scaffolds for different applications. The techniques I used were:

- Crystallization

- Textile formwork

While I worked alone with the crystallization process, Eldy, Ale and I worked together for the formwork generation.

Crystallization

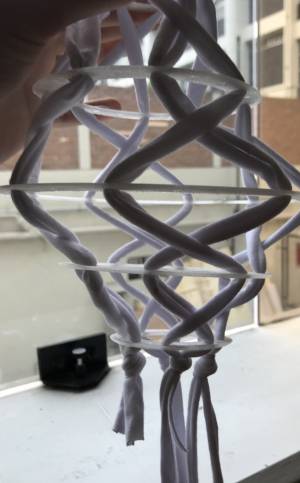

I wanted to create a lamp from the following shape:

In order to do so, I used Fusion 360 to model the circular structures:

In order to do so, I used Fusion 360 to model the circular structures:

And then I 3d printed them:

And then I 3d printed them:

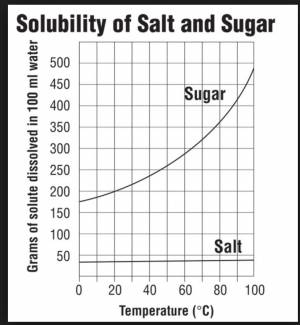

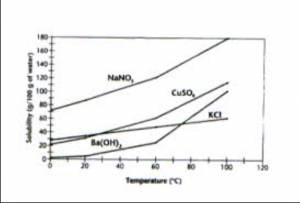

As for the crystallization process, I had the option to use either of the following solutes:

As for the crystallization process, I had the option to use either of the following solutes:

- Sugar

- Salt

- Copper Sulfate

- Borax

Choosing the best solute for the process wasn't hard when comparing each of the ingredient's solubility curves:

So, basically, it's easier to obtain sugar crystals than it is to obtain salt crystals, even though sugar crystals may take longer to form. Sulfate copper or borax crystals, however, are both easy obtaining and fast growing, so these were the solutes I chose.

So, basically, it's easier to obtain sugar crystals than it is to obtain salt crystals, even though sugar crystals may take longer to form. Sulfate copper or borax crystals, however, are both easy obtaining and fast growing, so these were the solutes I chose.

For the structure, I used the 3d printed rings and cotton fabric.

For the structure, I used the 3d printed rings and cotton fabric.

Borax crystals

According to the solubility curve, at 100°C, 520 grams of borax can be dissolved in a liter of water. Since I had only 50 grams of borax, I used 96 milliliters of water.

- 50 grams of borax

- 96 milliliters of water

I heated the water to a boiling point and then added it to a heat-resistant beaker which contained the 50 grams of borax. I also added green soap coloring.

I dipped a piece of fabric and let the solution cool overnight, covering it with film paper.

I dipped a piece of fabric and let the solution cool overnight, covering it with film paper.

Unfortunately, the crystals did not stick to the fabric the way I hoped they would, so I still haven't generated the structure I wanted.

Update

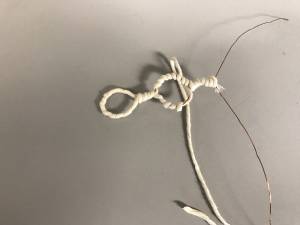

After a lot of trial and error, I decided to go to my university's chemistry investigation lab. There, they told me my original structure was way too big to be used, and that I needed to generate a new one. I used some copper wire and some thread and created an earring.

I used half a liter of water and 50 grams of borax to create the mix. First, I brought the water to a boiling point. Meanwhile, I ground the borax, so that the dissolution process was easier. When the water started boiling, I poured the salt in and mixed till nothing could be dissolved.

I used half a liter of water and 50 grams of borax to create the mix. First, I brought the water to a boiling point. Meanwhile, I ground the borax, so that the dissolution process was easier. When the water started boiling, I poured the salt in and mixed till nothing could be dissolved.

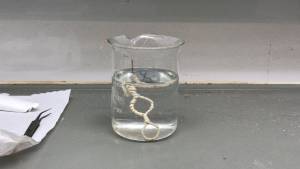

Finally, I inserted the earring and waited.

Finally, I inserted the earring and waited.

After about 8 hours, this was the result:

After about 8 hours, this was the result:

Textile Formwork

As for the second part of the assignment, I worked with Eldy and Ale in generating two structures.

Cement

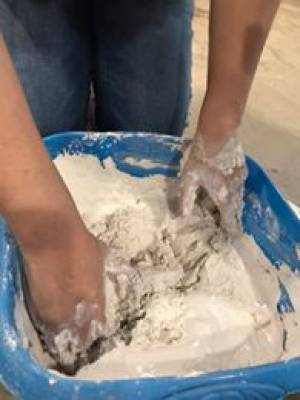

For the first structure, we used a laser cut frame and a piece of cotton fabric. once the main structure was assembled, we poured cement into the frame.

The cement consists of:

- 1 part water

- 5 parts cement mix