Open Source Hardware: From fibers to fabric

This week's assignment was to create a machine that generated a new fabric from fibers or other fabrics. Ale and I decided to work on a felting machine.

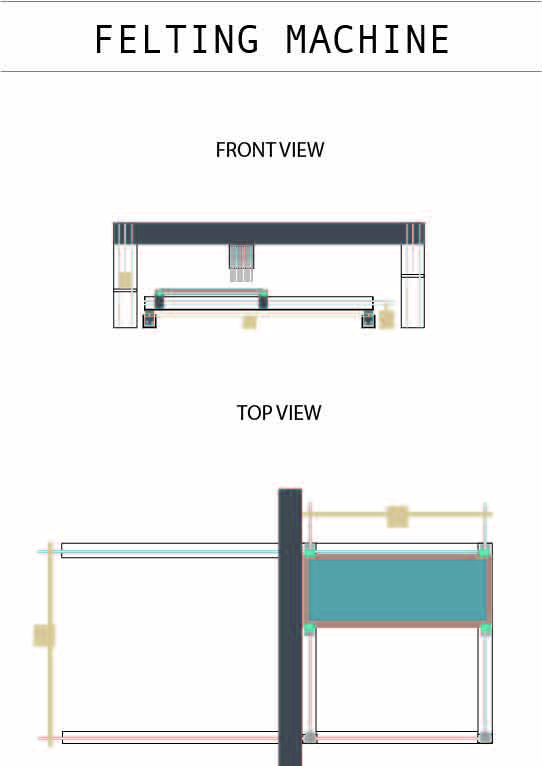

The idea was to join to natural fabrics with special needles, without using any sort of additional thread. Alexandra and I designed the mechanism based on how a 3D printer works. The original idea was to have a mobile set of needles, but after talking to an expert (All Patrix Anso) we decided that it was best to have a mobile bed instead.

After the design was finalized, it was time to start fabricating each part. I designed the rails using fusion 360, and then exported the sketch as a DXF file, in order to cut the parts using a shopbot router.

After cutting the parts, we started assembling them, however, I forgot to consider the tolerance of the material and the machine, thus it was necessary for us to start rasping the wood, for the pieces to fit.

This was the result once the main body was assembled.

We also used a modification of Nadya Peek's MTM boxes in order to create the mobile parts of the system. These were laser cut by Eldy.

For the bed, we designed an embroidery frame using laser cut MDF.

We also used Expanded Polystyrene for the bed.

As for the needle structure, we designed a way through which the user could easily modify the number of needles needed for the process, or, in case of rupture, change the whole set of needles without changing the structure. I designed a 3D printable case to serve as the main structure.

We used an oasis as a base where we could insert the needles, and used epoxy resin to fixate them.

After it was all designed, Luis helped us with the electronics. He started programming on Python using PY QT5 library to be able to interact with the program in a graphic way. The Gestalt nodes were used as drivers for the motors so the machine can move. We used NEMA17 stepper motors for the system.

You should check Ale's documentation, since she was the one leading the team and documenting as we fabricated.