Circular Open Source

Today the fashion industry is represented by fast fashion, mass consumption, copies from the biggest brands in less than one week, etc

But we can see some changes :

- DIY and DIT = makers movement

- Sharing of knowledge

- New fashion tools (CNC, 3D printing, laser cut, 3D printing, sewing machine, embrodery machine,…)

The intellectual property needs to change in Openness (Open source softwares/hardwares, Open design,Open data)

, the product has to turn into a platform and f ast fashion has to become slow again. We need to create a new ecosystem and a new circular economy.

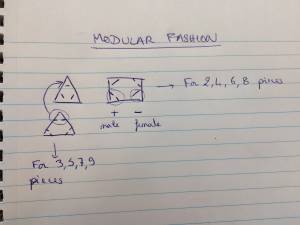

Modular Fashion

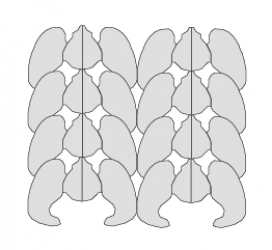

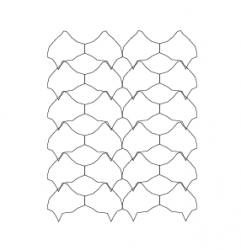

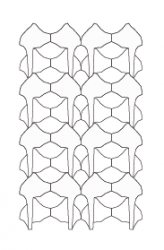

Modular fashion is a way of production that uses two-dimensional geometries and modular interlocking in the creation of a garment.

This process is called tesselation : it's a way of filling a plane with various geometries, infinitely replicated without overlapping or gaps.

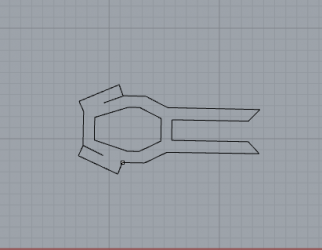

Every piece needs a male and female part so they can be assemble together :

Here are some example of shapes :

My project

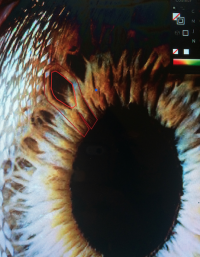

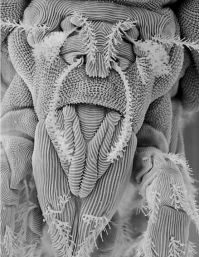

1. Inspirations :

2. Shape research :

- With Rhino :

- With Illustrator :

.

.

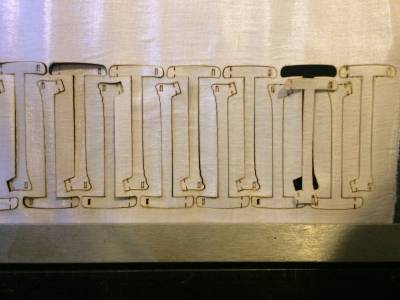

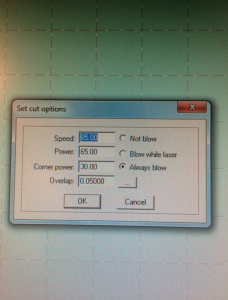

Then I tried to laser cut these shapes :

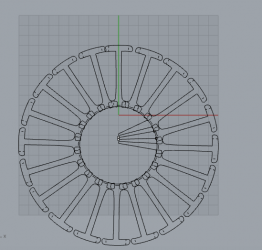

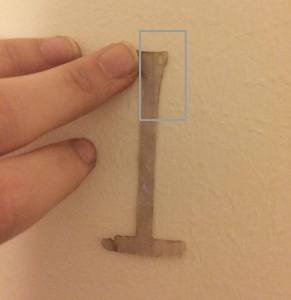

And I chosed this one :

I cut this shape “T” shape and assembled all of the shapes as a circle to obtain this module. The volume is created thanks to the inner cirle formed which is smaller than the circle going around.

Material used : jersey fused with snake skin pattern

But the fabric used was too soft and flappy so it was not keeping the shape the way I wanted.

On the other hand, this softness and flexibility allowed different kinds of volume which I also found interesting :

3. Material research :

Material used : blue fild

Material used : rigid white toile

The result was still too soft, so I tried to glue some fabric and plastic and finally got what I expected :

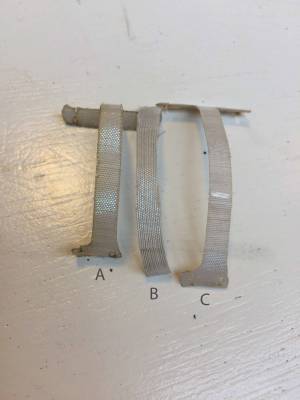

A : Fabric + glue + Mylar

B : Fabric + glue + Plastic

C : Fabric caught in between two layers of plastic thanks to the Thermal Laminator (but you loose the shining aspect of the fabric)

The Mylar was the best option, but really hard to find, you can only order it online, so wen I ran out of it I used another solution. I cut a sheet from a plastic roll at the lab, placed it between two sheets of plastic from the Thermal Laminator and fused them all together. The strength of the result was the same than the Mylar.

Unfortunately this material was burning in the laser cutting machine :

Then I realized that the burnt part was only on the plastic sheet in the middle and not on the plastic from the Thermal Laminator :

So I just fused a few plastic sheets from the Thermal Laminator together and there was no burning marks anymore :

4. Assembly :

I assembled all the pieces with each others, to get two different sizes of circles :

And started draping on the mannequin :