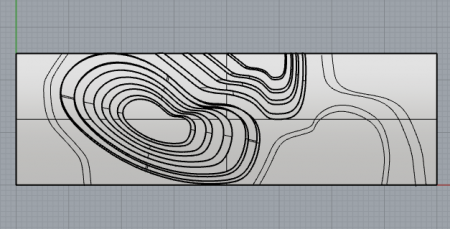

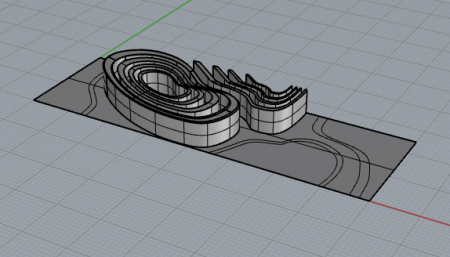

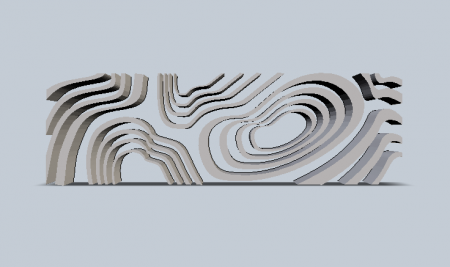

To practice 3D printing, I decided to create a watch wristlet for a project of my portfolio, inspired by macroscopic views of the Nature. The shapes are inspired by tree bark patterns and curves :

I first created a rectangle from the lenght of half a wrist (8cm) as a basis, and then drew on it 3D shapes with Rhino. Then I deleted the rectangle basis and exported the round shapes as a mesh and opened it on Cura to print.

Then I tried to 3D print the file :

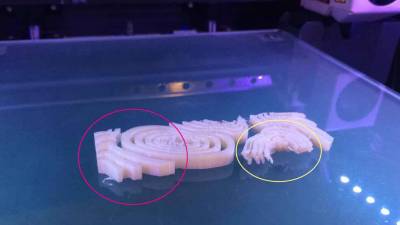

- 1st printing test :

It didn't work because I realized that the shapes were not properly closed on the bottom, so I had to stop the printing.

- 2nd printing test :

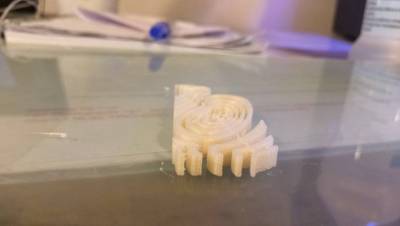

Better than the 1st one, but would have been better with a “support structure” (that you can separate from the shapes afterwords), because the shapes would really stay flat, and stuck to the support. Here I used only glue on the glass support of the machine and one of the circle moved during the printing which gave a different kind of shape :

+ VIDEO

Yellow = Part moving during the printing

Pink = Part not moving

Cura settings :

Export > Switch to quickprint :

- Choose material : PLA

- Choose profile : Fast print

- Print support structure : Yes

Export > Full settings :

- Layers height : 0,15

- Fill density: 100 ( = completely filled shape, stronger because really small and thin)

- Shell thickness : 0,8

- Print speed : 40

Machine settings :

- Utilities > Calibration > Bed calibration

- Printing temperature : 220°C

- Bed temperature : 55°C

The next step would be to link together all these round shapes together in a flexible way, so the wristlet can wind around the wrist smoothly. My firs idea is to merge the shapes onto liquid plastic, that would get solid when it cools down, mean while staying flexible.