week 4

Bio Fabric

Assignment | 17 oktober 2017

Explore (at least):

- 1 natural dye or bacterial dye

- 1 crafted or grown material

- Order, display, map & credit the process and results.

ref.: http://fabricademy.fabcloud.io/handbook/classes/03_biofabrics.html

Tanning Fish

- Read more about leather : Identify leather

- Youtube - “How fish leather is produced”

I liked the idea of trying to tan a fish skin. Looking on the internet I found 2 other methods then the one mentioned in the lecture. One recipe claims working with egg. Looking into process I found it mentioned on multiple occasions with fur tanning, but it's not clear to me why that would stop the decaying process. But it's simple enough to just try out. The second recipe is working with urine, essentially using that to create ammonia. But to make it less messy, skip that step, and just buy ammonia. And since it's rather similar to using ethanol (as in.. liquid that kills bacteria), which was sugested in the lecture, so I opted for that.

Process fish tanning (egg yolk)

Youtube : Fish leather tanning - egg yolk

- enjoy dinner but keep the skin (uncooked) ;)

- Remove scales and meat with a blunt object (aka. spoon)

- Rinse skin in cold soapy water

- Marinate skin for 15 minutes in : Egg yolk, table spoon dishwater soap and 100 ml vegetable oil

- Hang skin to dry for the night

- Break the skin to soften it

- Hang skin for 3 more day's

- Sand 'fleshy' side of skin

- Wax skin for looks (natural leather balm)

Process fish tanning (ethanol)

Youtube : Fish leather tanning - ammonia (part1) & tanning (part2).

- enjoy dinner but keep the skin (uncooked) ;)

- Remove scales and meat with a blunt object (aka. spoon)

- Rinse skin in cold soapy water

- Add equal parts ethanol & glycerol to glass bottle (with lid)

- Add skin to the bottle and leave it for 3 day's. (time in bottle varies depending on strength of ethanol).

- Shake bottle every once in a while

- Rinse skin in cold soapy water (to stop the process)

- Hang skin to dry

- Break the skin to soften it

- Sand 'fleshy' side of skin

- Wax skin for looks (natural leather balm)

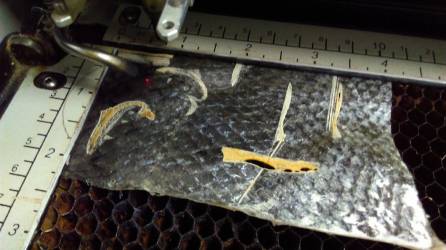

Preparation: scraping / washing

Preparation: prep both recipe

Cureing : skin spends 3 day's in jar + time in sun to dry

Post prep : scraping / sanding

Finishing : add wax

Tips and tricks from lecture

- You can add color to the tanning process by pre-dyeing the alcohol solution. This is done by adding natural dye extracts to the ethanol: such as hibiscus, red cabbage, beetroot, black beans liquor, turmeric etc.

- Laying the skin to dry with the scales facing down on a smooth surface will give you a shiny finish.

- Laying the skin to dry with the scales facing up will leave the scales side more open for a slightly rougher texture.

Result

Both recipes turned into a paper like material. The top one is the recipe with ethanol and the bottom one is with egg. For the ethanol recipe I made a small change, because at the time of starting this experiment I did not have the glycerol available. So this skin has been soaked in ethanol only.

The egg skin turned slightly more yellow of color. Both skins are semi translucent, which is rather nice. The difference between the 2 is stiffness and durability. The ethanol skin is more stiff then the egg one. And when sanding the skins, the egg skin is les sturdy, because I managed to sand a few tiny holes in the skin.

In the ammonia video the guy suggested to wring the skins with wax in a towel, to make sure the wax is really pushed into the fibers which I did. But I rather regret that because it made both my skins wrinkle a lot, which can not be undone.

Ethanol recipe version 2

So I had a salmon dinner again :P hence 2 new skins to try again. Now with glycerol added.

I repeated the process, one skin er jar. One jar filled with 15 gram glycerol & 15 gram ethanol. And the other with 30 gram glycerol and 15 gram ethanol. The result is that both skins are more supple then the skin without any glycerol in it. But both skins are still more stiff then I expected. And off course the skin with the most glycerol in it is the most flexible so far.

Also 2 small changes in the process. This time I skipped on the sanding. Since the skins are already scraped clean, it looked like that was already enough. And I also did not wring the wax into the skins with a towel but just rubbed it in with a piece of cloth.