week 7.1

The Textile Scaffold.

Assignment | 7 November 2017

Make a prototype of a technical textile application.

ref.: http://fabricademy.fabcloud.io/handbook/classes/06_textile_scaffold.html

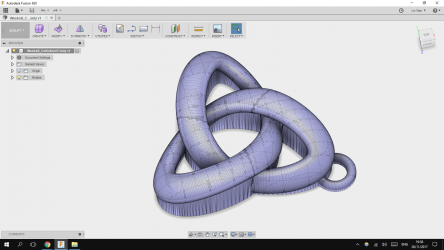

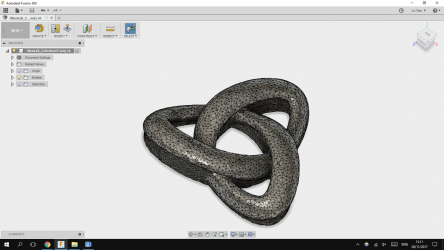

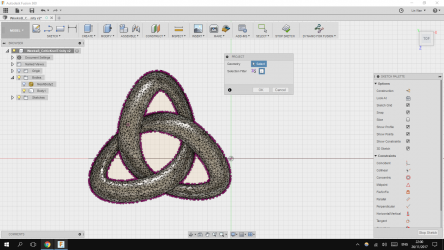

Mesh mode

To start I first need a model : https://www.thingiverse.com/thing:713270

- Modify > delete faces (remove the little ring)

- Modify > reduce (downsize model)

- Modify > remesh (recalculate geometry)

- Modify > scale (I used a sketch as template for reference).

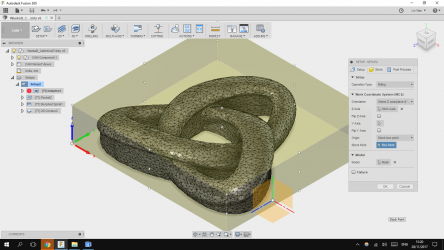

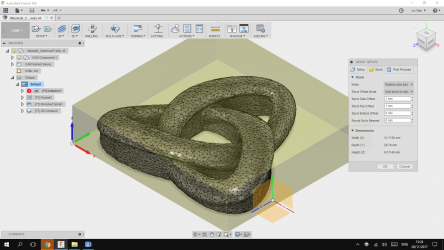

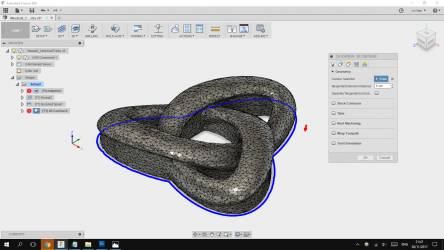

CAM mode

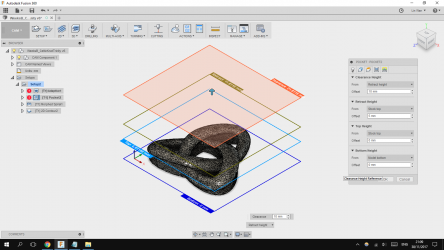

In setup you define the origin and stock size.

setup > new setup

add toolpath

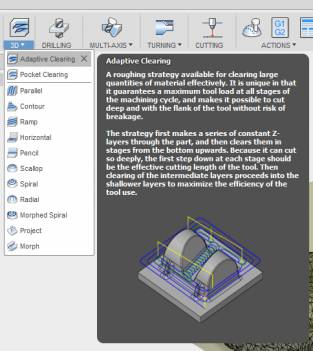

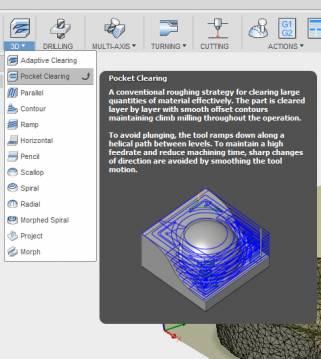

Now to choose an appropriate 3D toolpath. First step is understanding the difference between the top 2 toolpaths in the list. In hindsight, the description is accurate. :)

I first tried milling with the adaptive clearing toolpath. Which almost resulted in a broken tool. What I did not realize it will do, is use the entire length of the tool to push trough the material. The machine I am using is the Roland SRM-20 which is not strong enough to handle that kind of force.

So for me, using the pocket clearing is the way to go.

Pocket Setup (roughing toolpath)

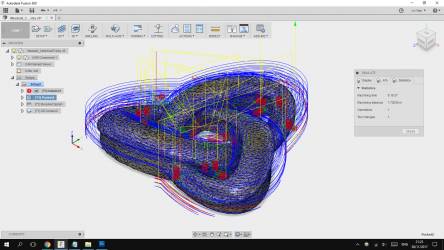

Morphed Spiral (finishing toolpath)

Define tool library

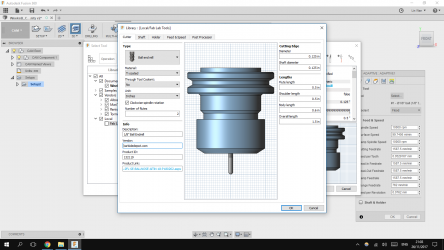

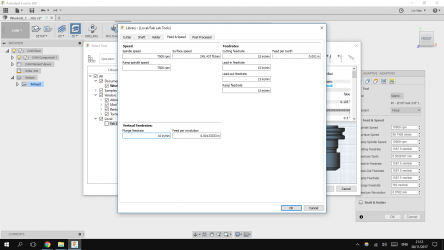

This is the first time I am using this CAM tool, so also the tool library needs to be created. The tool I'm using is a 1/8 inch, 2 Flute Ballnose from Carbide depot.

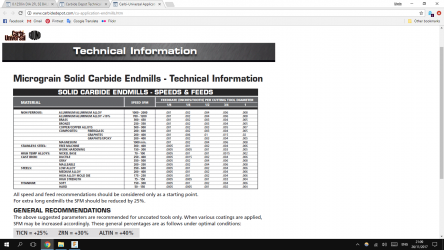

From the tool library I selected a generic ball nose mill, which I copied and then changed into what Im using. To start I first compare (or edit) the size of the cutter with the data stated on the website. On the website, linked under technical resources you can find a data sheet speed & feed recommendation.

2D countour (cut out toolpath)

In “model” mode I use the 'projection' to create a silhouette of the 3d file. This silhouette can then be used in CAM mode as a 2D contour toolpath.

Post processor

This will export the file to Roland milling file. This can be imported to Vpanel, which it the program that drives the milling machine.

CAM > Actions > Post process.