Week 7: Textile as Scaffold

The task: Use a different technique to make a prototype of a technical textile application

For this task I worked with Natalia and Pia. We wanted to experiment with different technologies and we decided on 3D printing, CNC milling as well as making a hand made cut out model.

Cut out model:

We used foam as it was easy to work with and readily available. We started out with a 8 x 10 cm cube which we then shaped into a 3D wave form. In order to put the scaffold on we sprayed the mold with non-stick spray and placed aluminum foil on it. From the tutorial we did with the rest of the class we knew this was necessary for the later removal of the scaffold. The composite scaffold was created by using 4 different types of material. Due to the wave shape of the mold we had to cut the material into small pieces in order for them to stay on the mold. We used wood glue to keep te materil in place. After a drying time of around 1 and ahf days we were able to successflly take the composite off the mold.

|  |

3D Print/ CNC mill:

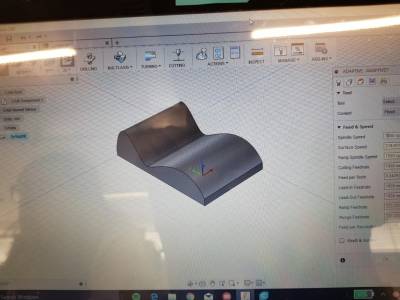

Becasue we wanted to see the effect of the different technologies we decided to use the same sahpe for the 3D print an CNC mill. We designed a replica of the hand cut wave model in Fusion360 and 3D printed. The CNC model was also made out of foam.

The same procedure was followed for the plastic and foam model as we did for the hand cut model. The only difference was that we used larger pieces of fabric for the CNC milled mold as we planned to place this in the vacuum press. We left the model in the vacuum overnight but unfortunately it became slightly disfigured because of it's size.

|  |  |

|  |  |

In the tutorial class with Adriana we experimented with cement and different materials to create unique shapes and models

|  |  |