Week 8: Open source hardware: from fibers to fabric

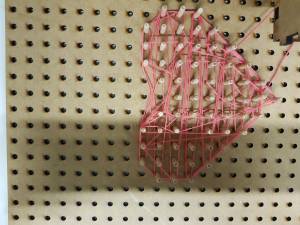

This assignment was rather daunting as it involved the goal was to make an automated machine. After some brainstorming we decided to make a joy stick operated String designer. (Traditionally made with nails on a wooden board, string/ yarn is threaded around the nails to make desired design)

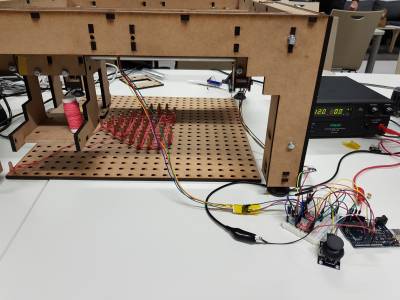

We took the opportunity to “hack” a previously made Fablab project, the PixelPlanter, http://archive.fabacademy.org/archives/2016/fablabkamplintfort/mtm-group.html

By hacking this machine we were able to use the existing motors and exterior frame.

Making the base

We chose to use wooden dowels instead of nails and designed the board in rhino

This design was then laser cut, we tested various settings in order to find the right one for the material we were suing - MDA 0.4 mm

To make the nozzle

We created a funnel like shape in Fusion 360 and 3D printed this.

Altering the motor

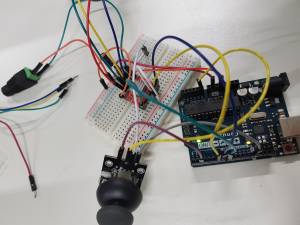

Components :

- Arduino Genuino

- Joystick

- 2 x Stepper Motor drivers

- 2 x 22 μF capacitors

- Lots of cables

- Power source

After a lot of tests, variations and help we got our machine to do what we wanted!

Improvements

- Make a flexible nozzle

- Computer programme the design - load an image which the machine then makes

- left/right control of joystick - the joystick wasnt moving in the left/right direction properly

- Tension on yarn

- Fix the base board

- Make a scaffold - glue/epoxy

Watch how it works:

|  |  |