Textile as Scaffold

Working in a group with Natalie & Laura we decided to try different technics of textile applications.

We created a handmade model out of foam. A disadvantage of creating it by hand is that the model might not turn out very neat. In this case it had no big negative influences on the finished result. The model was a 8 cm x 10 cm square with two little waves on it.

We created a handmade model out of foam. A disadvantage of creating it by hand is that the model might not turn out very neat. In this case it had no big negative influences on the finished result. The model was a 8 cm x 10 cm square with two little waves on it.

Using non stick spray we wrapped up the model in aluminum foil, hoping that removing the fabric from the model would be a little easier. We chose four different types of fabric and cut these into small pieces in order to layer them on to the model until it is fully coverd. With wood glue I stuck the first layer of fabric onto the model. After letting it dry for a few minutes I added the next layer of glue and farbic. I ended up repeating this procedure another three times. It took 1 1/2 days to dry completely. The fabric got really firm and stable and after removing the fabric from the model it stayed in shape. It was very surprising to me how stable it got.

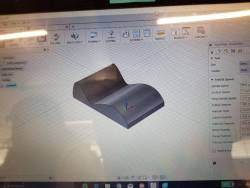

3D Printed Model

We decided to design a wave shape model in Fusion360 and printed the model in the 3D printer. For the other one we used the CNC milling machine. For the 3D printed one, we used the same technic as above. This time it was a little bit easier to apply the fabric because of the plastic model.

CNC Milling Model

For the CNC milling model we also used foam. We decided to use the vacuum machine. Again we used non stick spray and wrapped the model in aluminum foil. This time we did not cut the fabric into small pieces, instead we glued it tightly around the model. Again we used four different layers of fabric and put it into the vacuum machine overnight. Unfortunately, the foam model got crushed by the pressure of the machine. Maybe the foam is to “light“ for the vacuum machine or the model was just too small.

Besides that, we experimented with cement and different materials.