WEEK 08 | 14.11.17

Open source hardware: from fibers to fabric

Mar Canet & Varvara Guljajeva gave this lecture about the potential of the open source hardware in the area of textiles.

Here you can find well-documented notes about this topic.

The challenge for this week was to take advantage of digital fabrication and open source technology to come up with an open source machine for knitting, weaving or just invent new techniques or tools for this field.

WORKFLOW

As a group

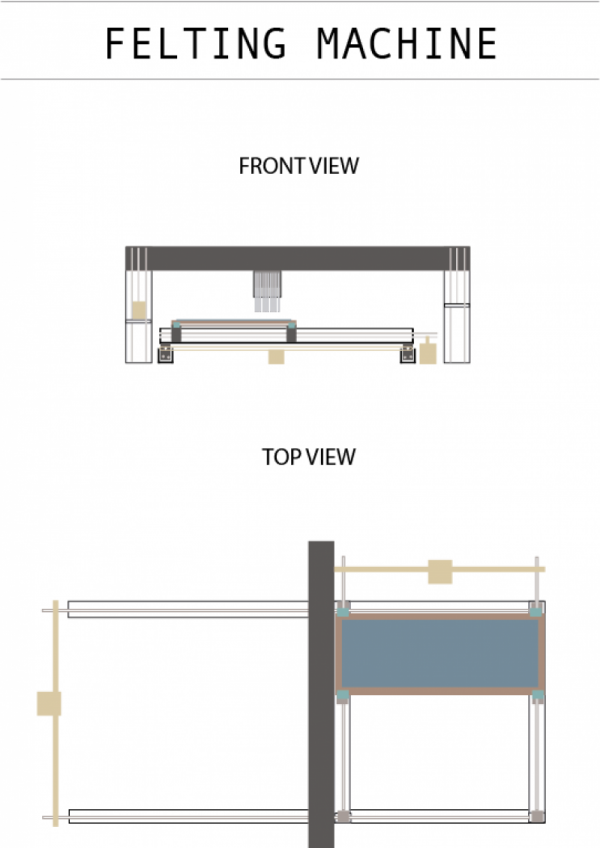

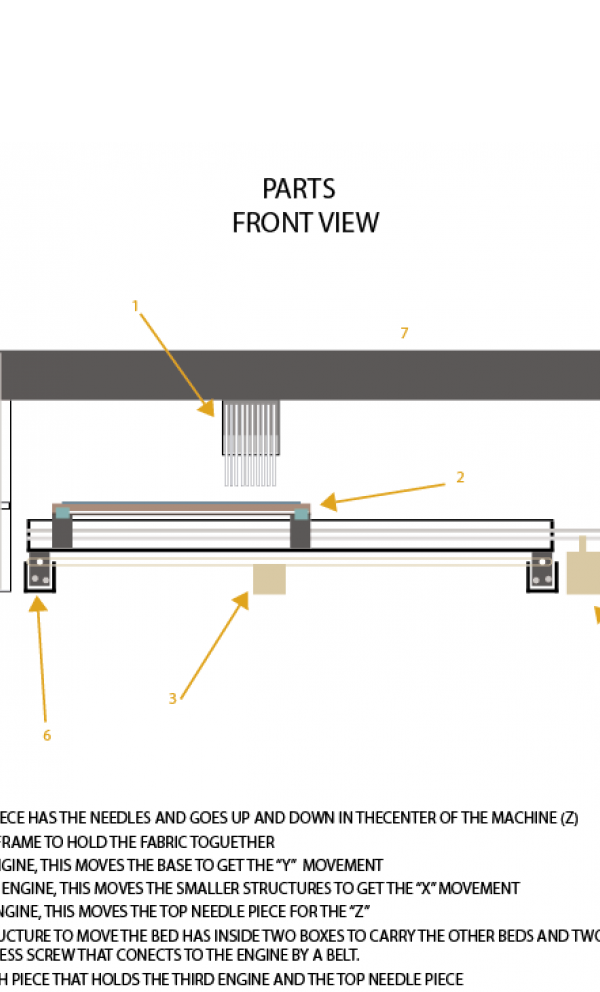

- We are still working on making a Needle felting machine.

- We worked in what we have more knowledge to be more efficient in the process of creation and fabrication.

- Ale and Carlos planned all the work and gave the main idea of this project.

- Luis works programming the felting machine and makes the electronics.

- I fabricate the pieces of the first prototype and redesigned some of them according to the changes and upgrades we made during the process of fabrication.

Individual

- I have never knitted so I decided to learn with a mini loom. For that, I printed a circular loom and started exploring and watching as many tutorials as I can.

Needle felting machine

Materials: Plywood 18mm., Plywood 4mm., electronic components, PLA

Machines: Shopbot, Laser cutter machine Speedy 400, Epilog laser mini, 3D Printer Felix 2.0

Frame: MDF 12mm

The process

1. You will find all the process details in Alexandra's page

Files

Knitting exercises

Materials: Antiallergic Wool Nº5, PLA

Machines: 3D Printer Felix 2.0